As sustainability becomes a top priority for businesses and consumers, the demand for biodegradable and eco-friendly packaging is growing rapidly. But is a biodegradable molded pulp tray insert the right choice for packaging tomato stew? How does it compare to traditional packaging materials? In this article, we will explore the benefits of paper molded packaging, why it is a superior option, and how it can help businesses reduce their environmental footprint.

What Is a Biodegradable Molded Pulp Tray Insert?

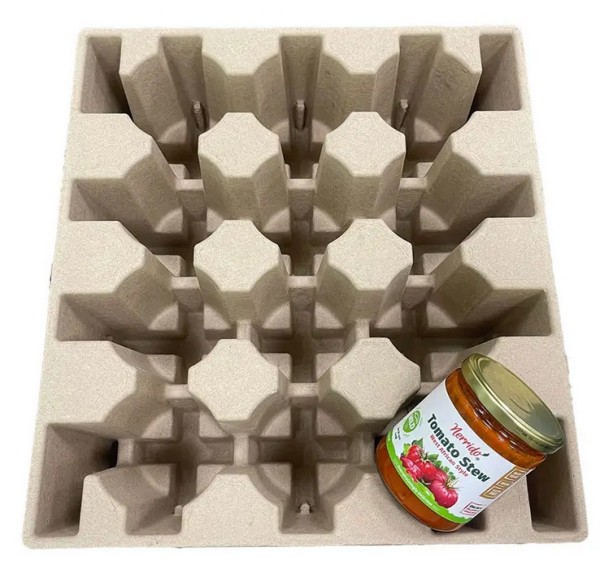

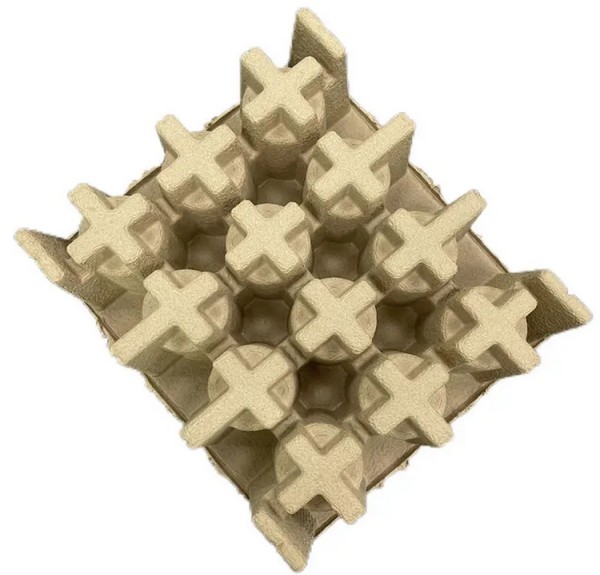

A molded pulp tray insert is a packaging solution made from recycled paper materials, such as cardboard or newspaper. These trays are molded into custom shapes to securely hold and protect products during transportation and storage. Unlike plastic trays, biodegradable molded pulp trays decompose naturally, making them an environmentally friendly alternative.

Why Choose Biodegradable Molded Pulp Tray Inserts for Tomato Stew Packaging? As sustainability becomes a top priority for businesses and consumers, more brands are seeking eco-friendly packaging solutions. One of the best alternatives to plastic is the biodegradable molded pulp tray insert, which is made from recycled paper pulp. This type of packaging is not only environmentally friendly but also durable and protective, making it ideal for food packaging, especially for tomato stew. But what are its real advantages, and is it truly a suitable choice for food packaging?

First and foremost, its biggest advantage is sustainability. Molded pulp tray inserts are made from recycled paper, sugarcane bagasse, and other natural fibers, making them 100% biodegradable and compostable. Unlike plastic, which can take hundreds of years to decompose, paper molded packaging naturally breaks down within a short period without leaving harmful residues. With more countries imposing restrictions on single-use plastics, businesses are now required to adopt eco-friendly packaging solutions. Using biodegradable molded pulp trays allows companies to stay compliant with environmental regulations while also enhancing their brand reputation. Beyond sustainability, molded pulp tray inserts offer excellent protective properties. Many people assume that paper-based packaging is fragile, but molded pulp trays are engineered to provide shock absorption and impact resistance. This makes them highly effective in protecting tomato stew containers from damage during transportation. Their custom-fit design prevents movement, reducing the risk of spills or leaks. Additionally, they can be treated with moisture-resistant coatings, ensuring durability even in humid environments. This is crucial for maintaining the integrity of food packaging and keeping products fresh. From a cost perspective, biodegradable molded pulp packaging is a cost-effective alternative to plastic. While plastic packaging may seem cheaper initially, increasing environmental regulations are making it more expensive to produce and dispose of. In contrast, paper molded packaging is made from readily available raw materials, keeping production costs low. Moreover, its lightweight design helps reduce transportation costs, making it an economical choice for food manufacturers.

Another major advantage is customization. Standard packaging may not meet the unique needs of different food products, but molded pulp tray inserts can be tailored to fit specific container shapes and sizes. Whether for single-serving tomato stew packaging or bulk food packaging, manufacturers can create trays with precise dimensions. Brands can also incorporate embossed logos and branding elements, enhancing product presentation and consumer appeal.For businesses looking to scale their operations, molded pulp packaging is highly suitable for large-scale production. Advances in manufacturing technology have made it possible to produce custom biodegradable packaging in bulk with fast turnaround times. This means businesses can switch to sustainable packaging without worrying about supply chain disruptions. Additionally, many manufacturers use sustainable sourcing methods, ensuring the entire production process is environmentally responsible. Switching to biodegradable molded pulp tray inserts is not just an eco-friendly decision but also a strategic business move. Consumers are becoming more environmentally conscious, and many actively seek out brands that use sustainable packaging. Using eco-friendly molded pulp trays can boost brand loyalty, increase sales, and help businesses stay ahead of sustainability trends.

In conclusion, biodegradable molded pulp tray inserts offer environmental benefits, durability, cost efficiency, and customization—making them an ideal choice for tomato stew packaging. As businesses strive to reduce their reliance on plastic, adopting paper molded packaging is a smart move that aligns with global sustainability efforts. If you’re looking for a reliable, eco-friendly, and high-quality food packaging solution, consider switching to molded pulp tray inserts. They offer the perfect balance between functionality, cost-effectiveness, and sustainability, helping businesses contribute to a greener future.