Businesses are shifting toward wet press molded pulp packaging as a sustainable and high-quality alternative to traditional packaging materials. With its smooth surface, high durability, and eco-friendly composition, this packaging solution is widely used for electronics, cosmetics, food containers, and protective packaging. This article explores the key benefits, applications, and why wet press molded pulp packaging manufacturers are essential for brands looking to enhance both sustainability and product presentation.

What Is Wet Press Molded Pulp Packaging?

Wet press molded pulp packaging is a premium packaging solution made from recycled paper fibers and processed using a high-pressure molding technique. Unlike dry-pressed molded pulp, the wet press process produces smoother, denser, and more refined packaging, making it ideal for brands that prioritize both aesthetics and functionality.

Key Bnefits of Wet Press Molded Pulp Packaging

1. Eco-Friendly & Biodegradable

As sustainability becomes a top priority, businesses are turning to wet press molded pulp packaging manufacturers for environmentally friendly alternatives. This type of packaging is:

✔ Made from recycled materials, reducing waste.

✔ 100% biodegradable and compostable, leaving no harmful residues.

✔ A sustainable replacement for plastic packaging, helping brands meet green packaging standards.

2. Superior Product Protection

Wet press molded pulp packaging provides excellent shock absorption and structural strength, ensuring fragile and high-end products are protected during shipping and handling. Its custom-fit molding also enhances impact resistance, reducing damage risks.

3. High-End Aesthetic Appeal

Unlike traditional molded pulp packaging, the wet press process results in a smooth and refined surface, making it perfect for luxury product packaging. The high-quality finish allows brands to customize their logo, embossing, and branding elements effectively.

4. Cost-Effective & Customizable

Working with a custom wet press molded pulp packaging supplier allows businesses to design custom-fit packaging for their products, reducing excess material waste. Despite its premium quality, wet press molded pulp remains a cost-effective option compared to other sustainable packaging alternatives.

Applications of Wet Press Molded Pulp Packaging

The versatility of wet press molded pulp packaging makes it ideal for various industries:

- Electronics Packaging – Protects devices like smartphones, headphones, and accessories.

- Luxury Goods – Used for high-end cosmetics, perfumes, and gift boxes.

- Food & Beverage – Perfect for eco-friendly food trays, cup holders, and takeout containers.

- Medical & Healthcare – Secure packaging for pharmaceutical and medical devices.

How to Choose the Right Wet Press Molded Pulp Packaging Manufacturer?

Partnering with a reliable wet press molded pulp packaging supplier ensures high-quality packaging that meets your business needs. When selecting a manufacturer, consider:

✔ Experience & Expertise – Choose a supplier specializing in custom molded pulp solutions.

✔ Material Quality – Ensure they use premium recycled paper fibers for enhanced durability.

✔ Customization Capabilities – Look for options like color variations, embossing, and tailored fit designs.

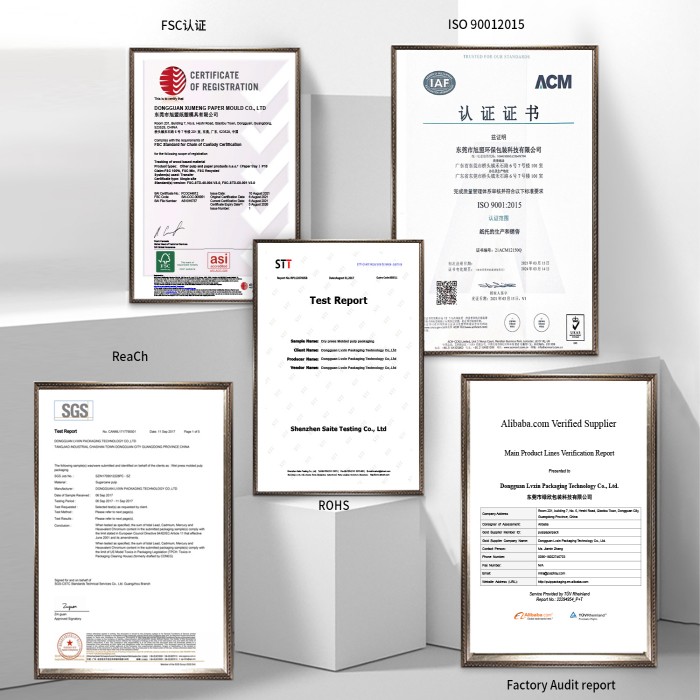

✔ Sustainability Certifications – Verify their compliance with eco-friendly packaging standards.

Conclusion:

As more businesses prioritize sustainability and high-quality packaging, wet press molded pulp packaging stands out as an ideal choice. With eco-friendliness, durability, and aesthetic appeal, it provides a premium yet sustainable packaging solution. For brands looking to switch to custom wet press molded pulp packaging, working with a trusted wet press molded pulp packaging manufacturer ensures a seamless and high-quality packaging experience. Invest in sustainable packaging today and elevate your brand’s impact!