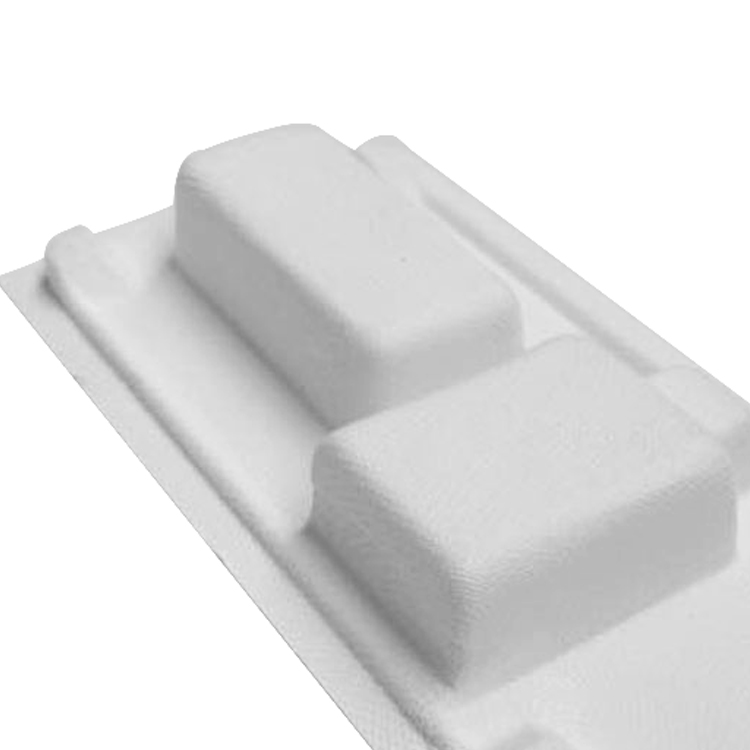

Wet press moulded pulp trays have emerged as a sustainable packaging solution, offering eco-friendly alternatives to traditional plastic packaging. As businesses increasingly prioritize sustainability and cost-efficiency, the question arises: Are wet press moulded pulp trays cost-effective for businesses? In this article, we'll delve into the various factors influencing the cost-effectiveness of wet press moulded pulp trays and their potential benefits for businesses.Wet press moulded pulp trays are made from a mixture of recycled paper fibers and water, which is formed into the desired shape using molds and then dried to create sturdy and biodegradable packaging solutions. These trays are commonly used for packaging products such as fruits, eggs, electronics, and cosmetics, among others. Wet press molded pulp trays offer several advantages, including sustainability, biodegradability, and excellent protective properties.

① Factors Influencing Cost-Effectiveness

Material Costs:

One of the primary considerations in assessing the cost-effectiveness of wet press moulded pulp trays is the cost of materials. Compared to traditional plastic packaging materials, the cost of recycled paper fibers used in wet press moulded pulp trays may vary depending on factors such as availability, demand, and quality.

Manufacturing Costs:

The manufacturing process of wet press moulded pulp trays involves several steps, including pulping, molding, pressing, and drying. The equipment, labor, and energy required for these processes contribute to the overall manufacturing costs. Efficiency in production and economies of scale can help reduce manufacturing costs and improve cost-effectiveness.

Customization Costs:

Businesses may incur additional costs for customizing wet press moulded pulp trays to meet their specific requirements, such as size, shape, color, and branding. While customization adds value and differentiation, it may also increase production costs, affecting overall cost-effectiveness.

Transportation Costs:

Another factor to consider is the transportation costs associated with wet press moulded pulp trays. These trays are lightweight and stackable, which can reduce transportation costs compared to heavier and bulkier packaging materials. However, transportation distance, mode of transportation, and fuel prices can impact overall transportation costs.

End-of-Life Costs:

Wet press moulded pulp trays are biodegradable and can be recycled or composted at the end of their life cycle, reducing disposal costs and environmental impact. However, businesses need to consider the logistics and costs associated with collection, recycling, or composting facilities to ensure proper disposal of used trays.

② Benefits for Businesses

Sustainability:

Wet press moulded pulp trays offer businesses an opportunity to align with sustainability goals and reduce their environmental footprint. Using biodegradable packaging materials can enhance brand reputation and appeal to eco-conscious consumers, leading to increased customer loyalty and market share.

Regulatory Compliance:

With increasing regulations and consumer demand for sustainable packaging solutions, businesses can stay ahead of compliance requirements by adopting wet press moulded pulp trays. Compliance with environmental standards and regulations can mitigate risks and ensure business continuity.

Brand Differentiation:

Customizable wet press moulded pulp trays allow businesses to showcase their brand identity, values, and messaging through packaging design and branding. Unique packaging designs and eco-friendly branding can differentiate products in the market and attract consumers' attention.

Cost Savings:

While the initial investment in wet press moulded pulp trays may be higher than traditional plastic packaging materials, businesses can achieve long-term cost savings through reduced material costs, transportation costs, and disposal costs. Efficiency improvements in manufacturing processes can further enhance cost-effectiveness over time.

In conclusion, wet press moulded pulp trays offer businesses a cost-effective and sustainable packaging solution that aligns with evolving consumer preferences and regulatory requirements. While the initial investment and customization costs may vary, the long-term benefits in terms of sustainability, brand differentiation, and cost savings outweigh the upfront expenses. By adopting wet press moulded pulp trays, businesses can demonstrate their commitment to sustainability, enhance brand value, and drive profitability in the competitive marketplace.