Molded pulp boxes, alternatively referred to as biodegradable pulp boxes or pulp mold boxes, are increasingly recognized as eco-friendly packaging choices in diverse sectors. A prominent attribute of these containers lies in their adaptability for customization, affording enterprises the flexibility to craft packaging solutions aligned with their unique specifications and branding preferences. This piece aims to explore the spectrum of customization avenues provided by molded pulp boxes and their role in fostering sustainable packaging practices.

一. Understanding Molded Pulp Boxes

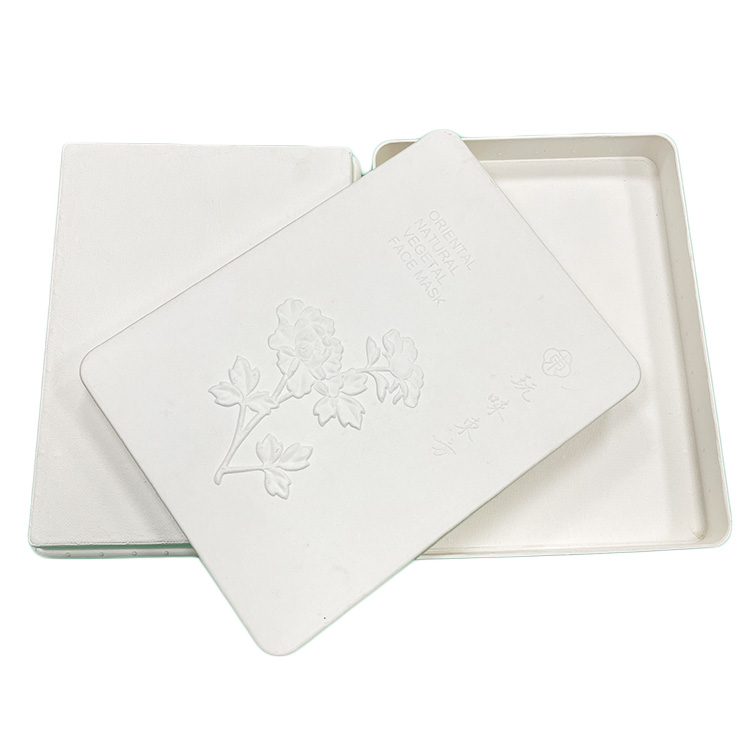

Molded pulp boxes are made from a mixture of recycled paper fibers and water, which are formed into the desired shape using molds and then dried to create sturdy and eco-friendly packaging solutions. These boxes are known for their excellent protective properties, biodegradability, and low environmental impact, making them ideal for a wide range of applications, including electronics, food and beverage, cosmetics, and more.

Types of Customization Options

1. Shape and Size:

One of the primary customization options for molded pulp boxes is the ability to create boxes in various shapes and sizes. Whether it's a simple rectangular box or a more complex design with compartments and dividers, molded pulp manufacturers can accommodate a wide range of packaging requirements.

2. Color:

Molded pulp boxes can be customized with different colors to match brand identities or product aesthetics. While natural brown is the standard color for molded pulp, manufacturers can use pigments or dyes to achieve custom colors that resonate with brand messaging and visual identity.

3. Texture and Finish:

Molded pulp boxes can be finished with different textures and surface treatments to enhance their visual appeal and tactile experience. Options such as matte or glossy finishes, embossed logos or patterns, and textured surfaces can add a premium look and feel to the packaging.

4. Branding and Printing:

Molded pulp boxes offer opportunities for branding and printing to communicate product information, logos, and promotional messages effectively. Printing options include flexographic printing, digital printing, or labeling, allowing businesses to achieve high-quality graphics and text on their packaging.

5. Inserts and Cushioning:

Custom inserts and cushioning can be integrated into molded pulp boxes to securely hold and protect products during shipping and handling. Inserts can be tailored to fit specific product dimensions and shapes, providing added protection against damage and ensuring a positive unboxing experience for customers.

Benefits of Customization

二. Brand Differentiation:

Customized molded pulp boxes help brands stand out in a competitive market by conveying a unique identity and value proposition. Custom colors, logos, and designs create memorable packaging experiences that leave a lasting impression on consumers.

1. Product Protection:

Tailored inserts and cushioning solutions protect products from damage during transit, reducing the risk of returns and enhancing customer satisfaction. Customized packaging ensures that products arrive in pristine condition, reinforcing brand trust and loyalty.

2. Sustainable Brand Image:

By opting for biodegradable pulp boxes and incorporating eco-friendly design elements, brands can reinforce their commitment to sustainability and environmental responsibility. Customized packaging communicates a brand's values and resonates with environmentally conscious consumers.

3. Enhanced Marketing Opportunities:

Custom printing and branding options on molded pulp boxes provide additional marketing opportunities for brands to showcase product features, benefits, and storytelling. Eye-catching graphics and messaging capture consumer attention and encourage brand engagement.

In summary, molded pulp boxes offer a wide range of customization options that enable businesses to create unique and sustainable packaging solutions tailored to their specific needs and branding requirements. From custom shapes and colors to branded printing and inserts, molded pulp manufacturers provide versatile solutions that enhance product protection, brand differentiation, and marketing opportunities. By leveraging the customization capabilities of molded pulp packaging, brands can elevate their packaging strategy, strengthen consumer relationships, and contribute to a more sustainable future.