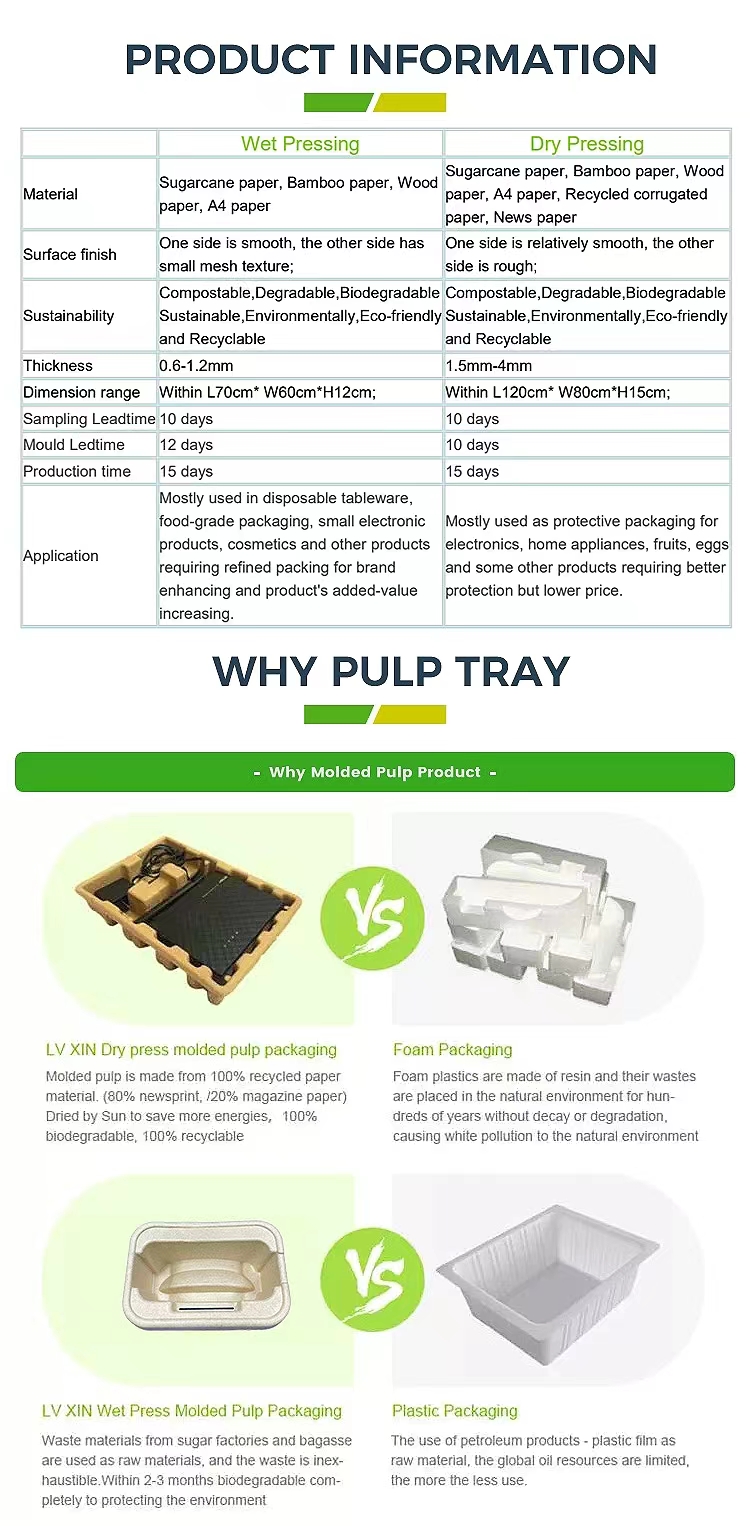

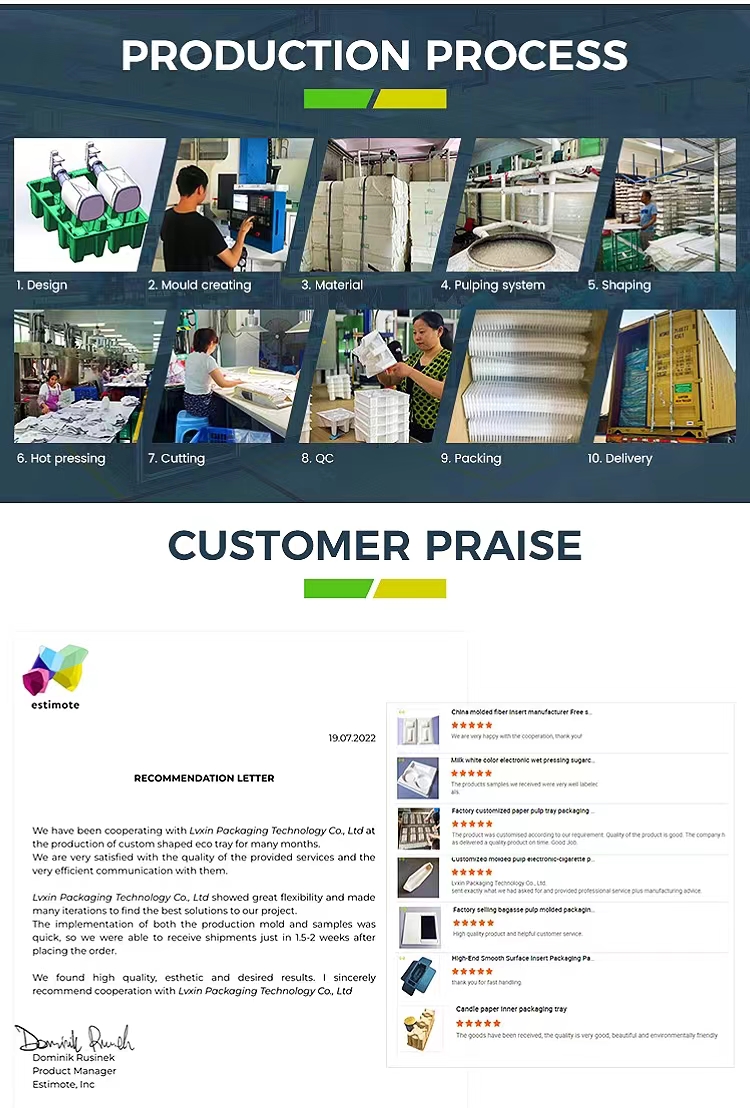

With a strong focus on sustainability, Pulp tray for electronics is made from biodegradable materials that break down naturally over time, reducing the environmental impact. By choosing our recyclable pulp molded packaging, you are making a conscious choice to support a greener future.Thank you for your effort to protect the earth.