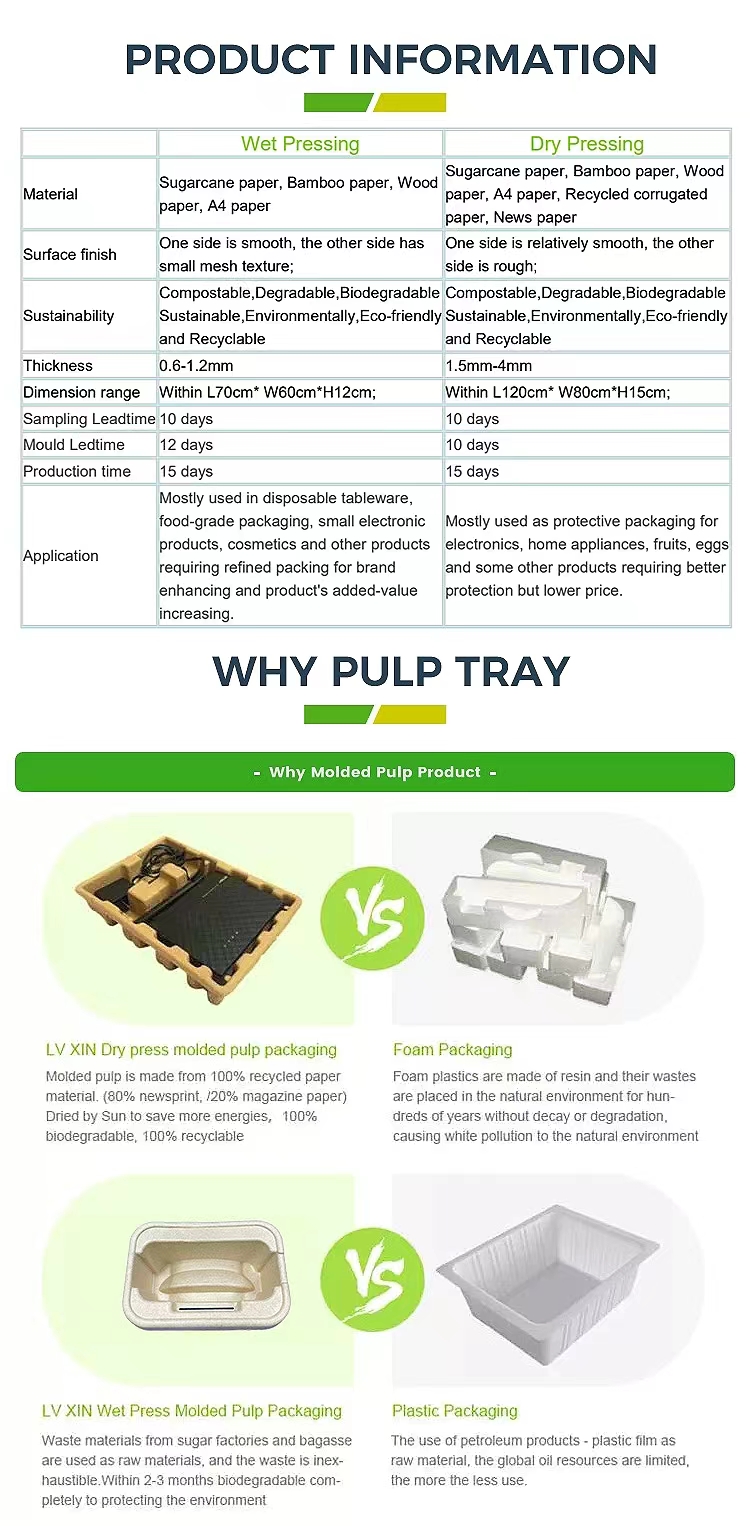

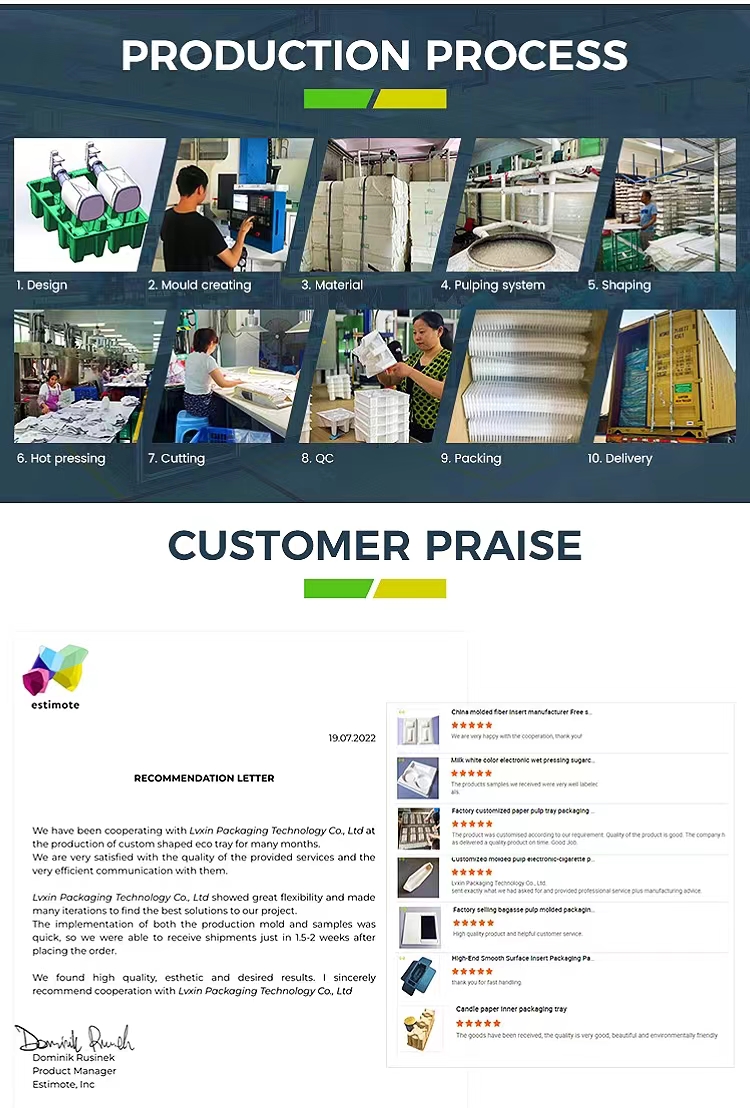

The sustainable wet press moulded pulp inner tray is an eco-friendly packaging solution designed for protecting and securely holding products. Made from biodegradable and recyclable materials, this tray provides sturdy support while reducing environmental impact. Ideal for electronics, cosmetics, and other fragile items, it offers a sustainable alternative to plastic or foam inserts.