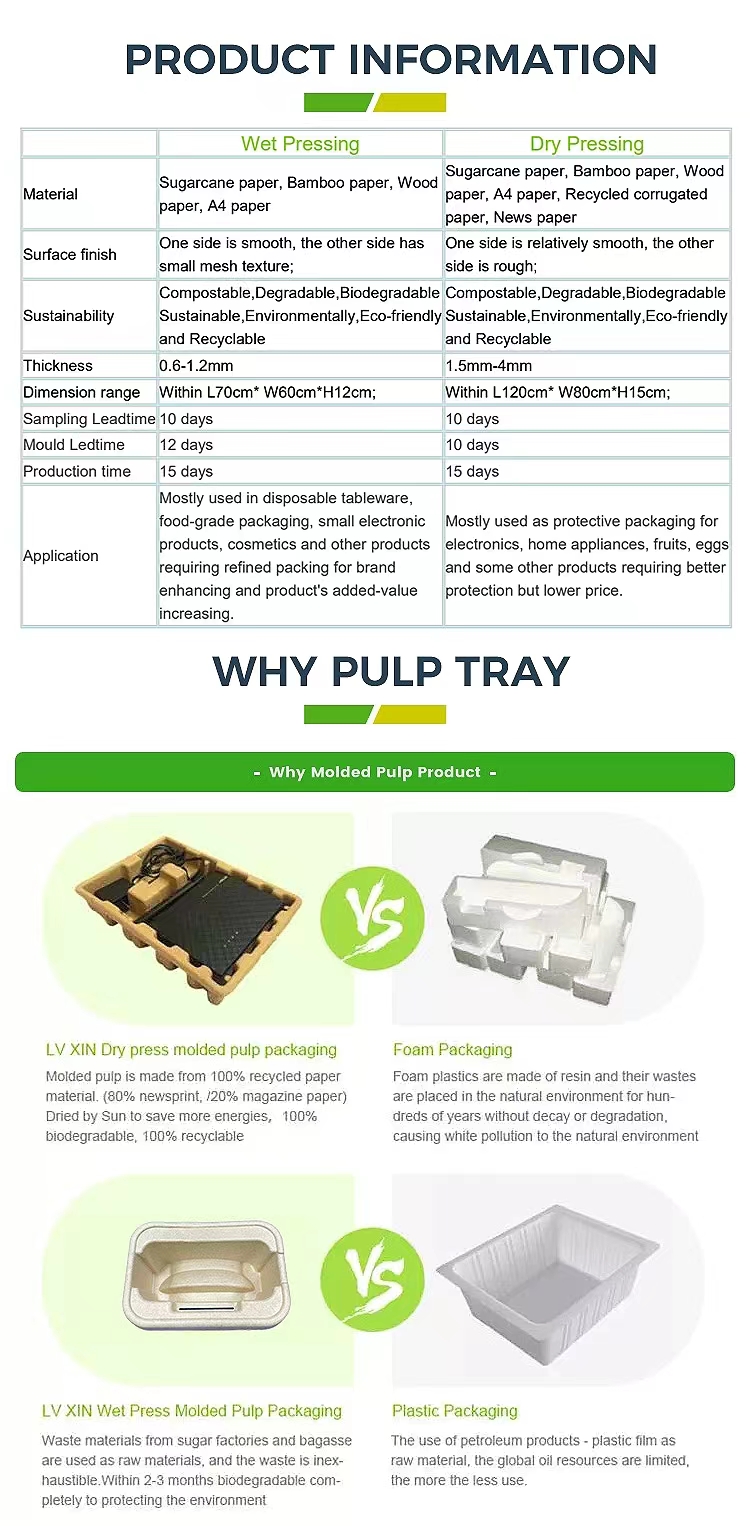

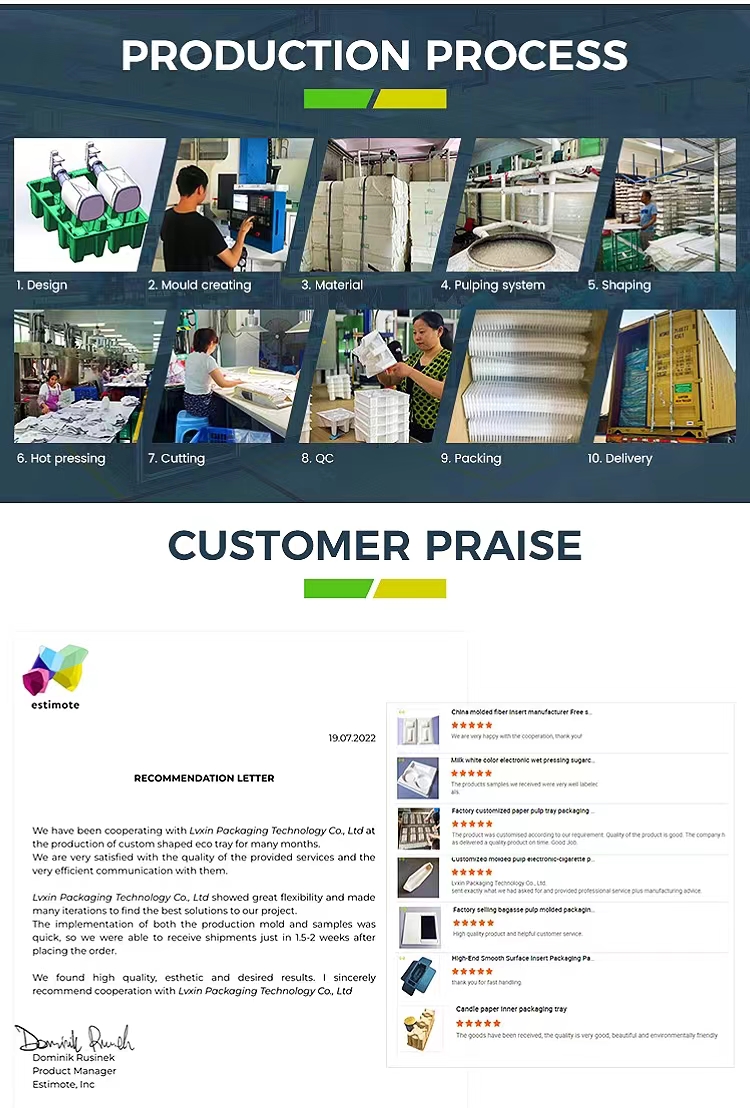

Our disposable packaging molded paper pulp inner trays are an eco-friendly and cost-effective solution for product protection and display. Made from biodegradable and recyclable paper pulp, these trays are perfect for securely holding items such as electronics, cosmetics, and fragile products. Their molded design ensures a snug fit, minimizing movement and damage during transit. Ideal for businesses looking to enhance sustainability without compromising on quality and functionality.