Wet press bamboo pulp trays are eco-friendly, biodegradable packaging solutions made from sustainable bamboo fibers. They are created using the wet press process, ensuring a smooth, durable, and high-quality finish.

Product Model : Wet press bamboo pulp tray custom bamboo pulp tray biodegardable bamboo pul tray

Product ID :

Wet press bamboo pulp trays are eco-friendly, biodegradable packaging solutions made from sustainable bamboo fibers. They are created using the wet press process, ensuring a smooth, durable, and high-quality finish.

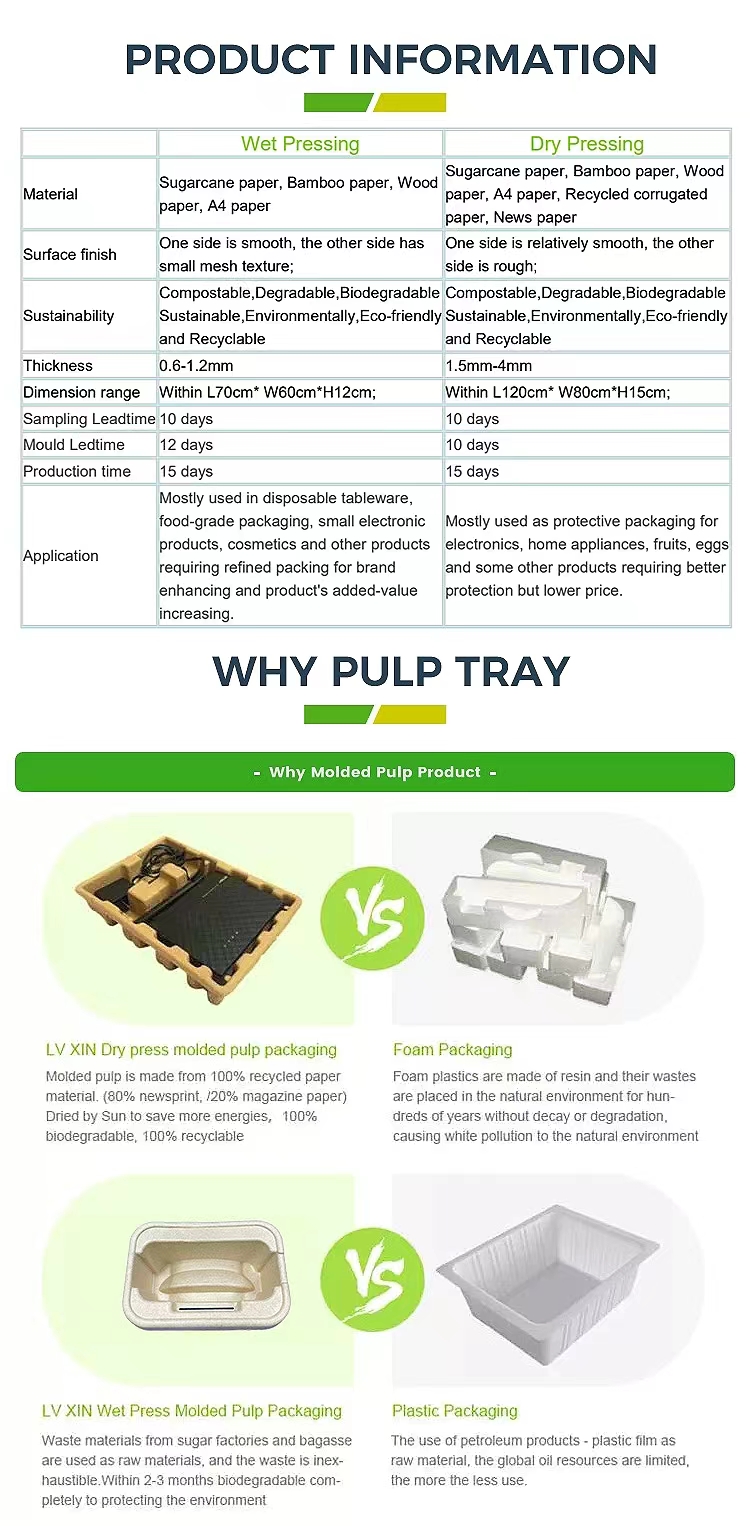

Wet Press Bamboo Customized Pulp Trays are a sustainable and versatile packaging solution designed to meet the unique needs of various industries. Made from renewable bamboo pulp and formed using an advanced wet pressing technique, these trays provide an eco-friendly alternative to traditional packaging materials.

Key Features:

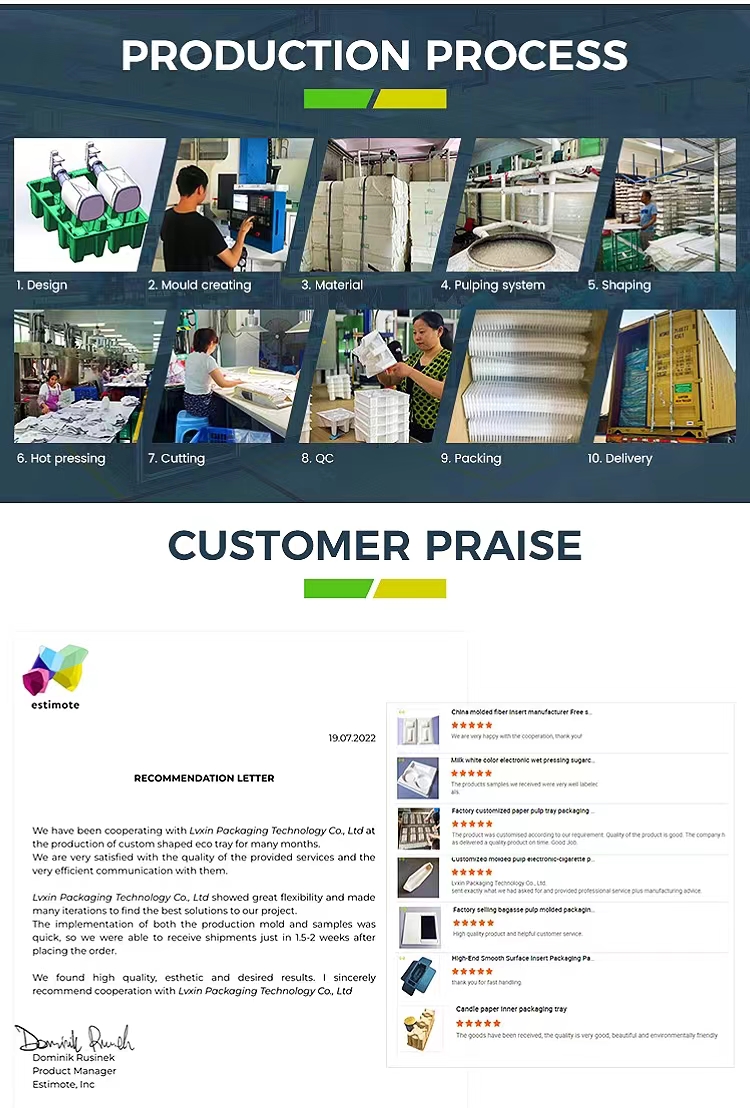

With a strong focus on sustainability, our packaging is made from biodegradable materials that break down naturally over time, reducing the environmental impact. By choosing our recyclable pulp molded packaging, you are making a conscious choice to support a greener future.

QWhat are the benefits of using molded pulp packaging?

QWhat are the applications of molded pulp packaging?

Color moulded pulp tray

wet press mould pulp box

LVXIN mould pulp box

Recycled paper pulp tray moulded pulp paper tray manufacturing

Eco-friendly black mould pulp for sustainable production

Dry press recycle paper pulp