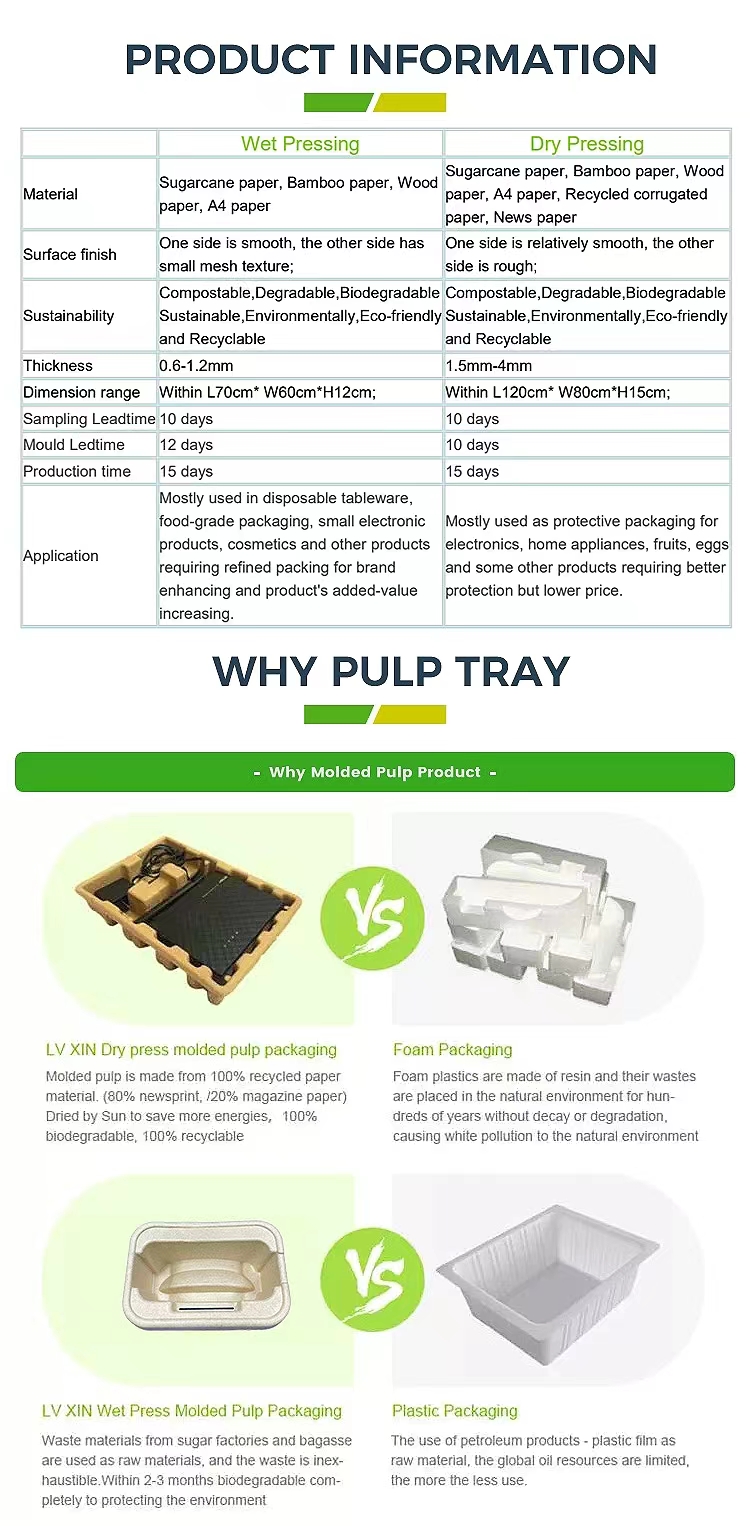

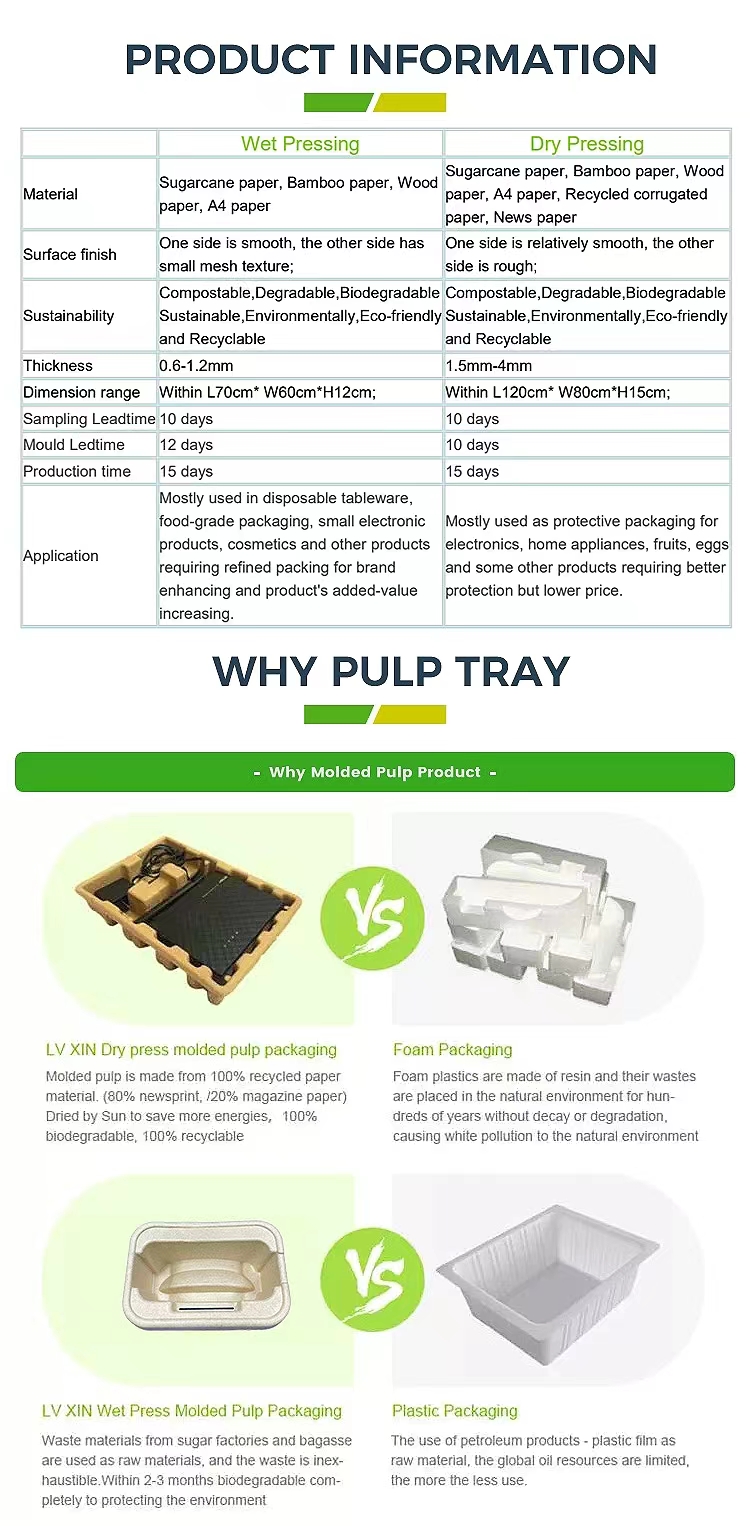

Our wet molded pulp customized offers tailored solutions for creating high-quality, eco-friendly molded pulp products that meet your specific requirements. Whether you need packaging, industrial parts, or consumer goods, our service ensures that your products are designed and manufactured to the highest standards. With a focus on sustainability and precision, we deliver bespoke molded pulp solutions that align with your brand and environmental goals.

Key Features

1. Bespoke Design

We collaborate closely with you to design custom shapes, sizes, and structures that perfectly match your product’s specifications, ensuring functionality and aesthetics.

2. Eco-Friendly Materials

Our molded pulp products are made from 100% recycled paper, providing an environmentally sustainable option that reduces waste and carbon footprint.

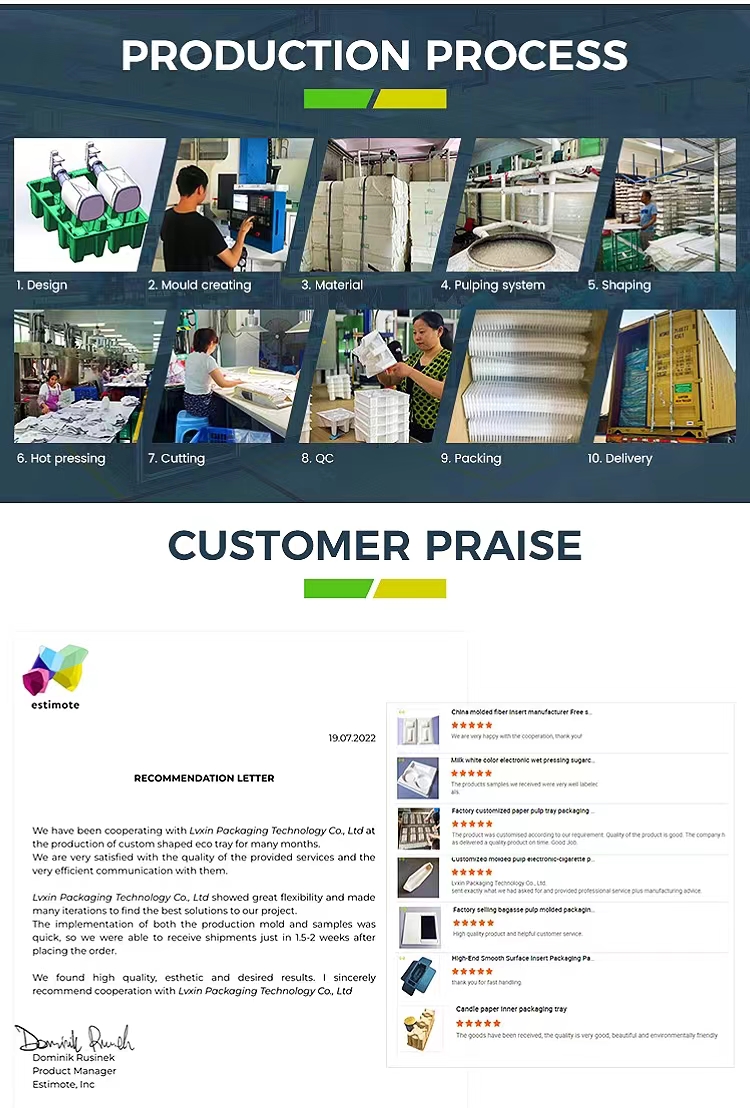

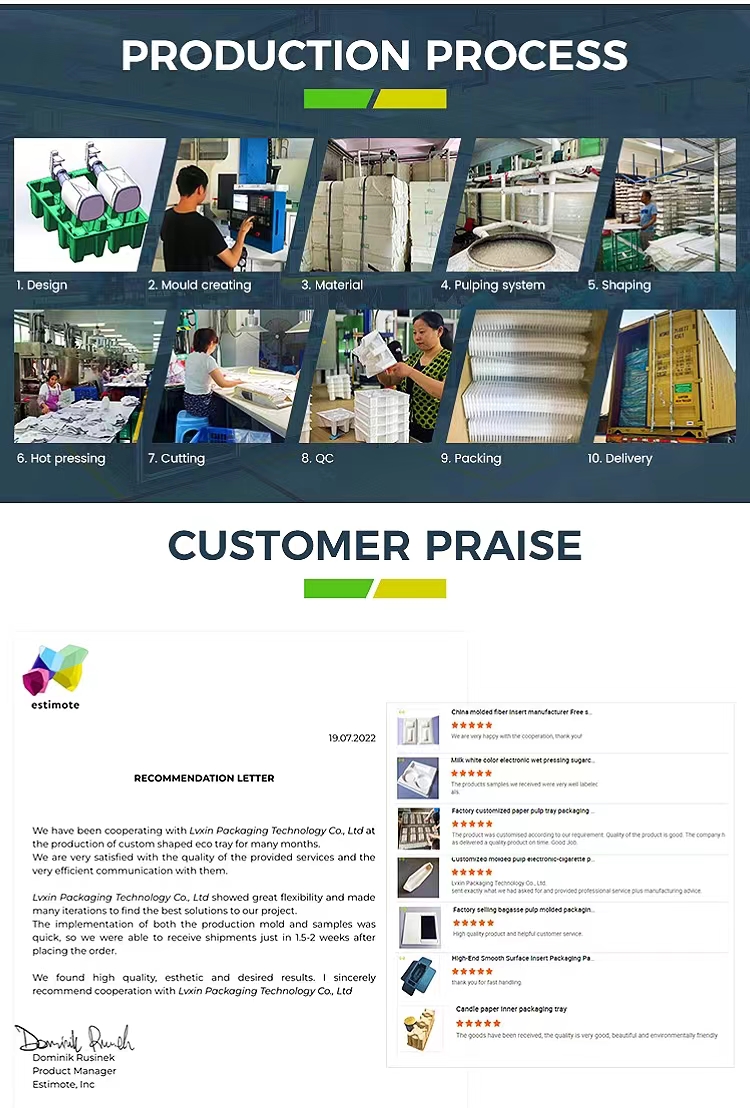

3. Advanced Manufacturing Process

Utilizing state-of-the-art wet molding technology, we achieve superior product strength, smooth surfaces, and detailed textures, ensuring a premium finish.

4. Versatile Applications

Suitable for a wide range of industries, including electronics, food and beverage, consumer goods, and more. Our service adapts to various needs, from protective packaging to aesthetically pleasing retail displays.

5. Comprehensive Support

From initial concept to final production, our expert team provides comprehensive support, including design consultation, prototyping, and full-scale production.