If you want to know extact price.please help to share yourmaterial,size,logo printingwith us,then the best price will be offer in soonest, thanks a lot !

Product Model : A paper tray for holding candles

Product ID : 60705515488

If you want to know extact price.please help to share yourmaterial,size,logo printingwith us,then the best price will be offer in soonest, thanks a lot !

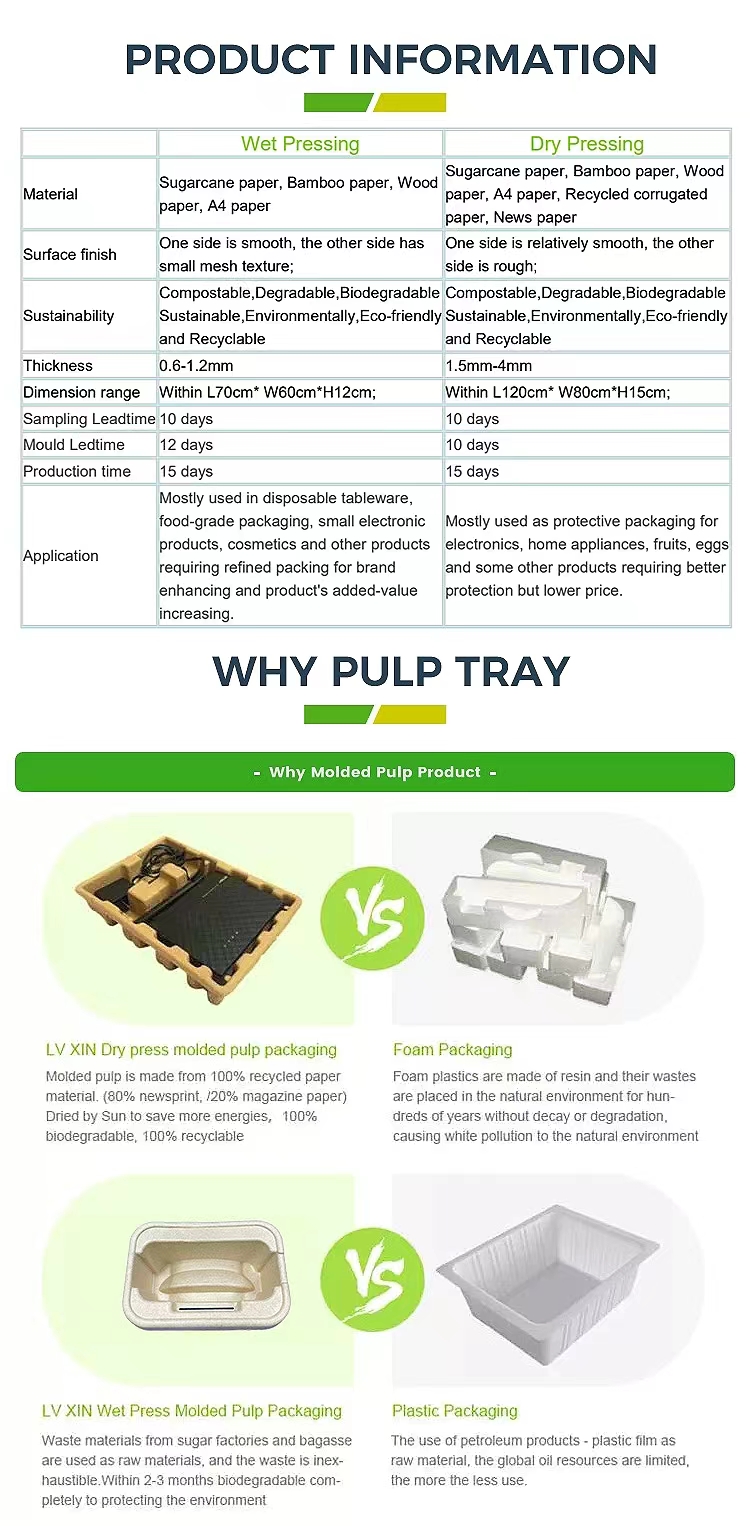

Dry pressing molded pulp is an advanced and eco-friendly material used for creating various molded products through a dry pressing process. This method produces durable, high-quality pulp products suitable for packaging, disposable tableware, and protective cushioning. The dry pressing technique ensures a smooth surface and consistent density, making it ideal for applications where precision and strength are required.

Key Features

1. Enhanced Durability

The dry pressing process creates a denser and stronger material compared to traditional wet pressing, providing superior durability and resistance to impact and wear.

2. Eco-Friendly

Made from recycled paper pulp, our dry pressing molded pulp products are biodegradable and environmentally friendly, contributing to sustainable practices.

3. Precision Molding

The dry pressing technique allows for high precision in molding, resulting in products with smooth surfaces and accurate dimensions.

4. Customizable

Available in various shapes, sizes, and thicknesses, our dry pressing molded pulp can be customized to meet specific requirements for different applications.

5. Cost-Effective Production

Efficient manufacturing processes reduce production costs while maintaining high product quality, making it a cost-effective solution for large-scale production.

Dedicated to providing eco-friendly packaging solutions for our customers. Our sustainable packaging paper pulp products are designed with a focus on environmental responsibility and reducing waste. Our sustainable packaging paper pulp products offer a range of benefits. Firstly, they are biodegradable and compostable, making them an ideal choice for customers who prioritize environmental friendliness. These products break down naturally over time, reducing the burden on landfills and minimizing long-term environmental impact. By choosing our sustainable packaging paper pulp products,you not only contribute to reducing your environmental footprint but also demonstrate your commitment to corporate social responsibility. Together, let's make a positive impact on the environment and promote a greener future with our sustainable packaging solutions.

QWhat is the cost of molded pulp packaging?

QWhat is the future potential of molded pulp packaging?

QIs molded pulp packaging suitable for food and beverage products?

QWhat are the applications of molded pulp packaging?

QWhat are the benefits of using molded pulp packaging?

QHow is molded pulp packaging made?

Color moulded pulp tray

wet press mould pulp box

LVXIN mould pulp box

Recycled paper pulp tray moulded pulp paper tray manufacturing

Eco-friendly black mould pulp for sustainable production

Dry press recycle paper pulp