As sustainability becomes a top priority across industries, more companies are shifting from plastic and foam packaging to eco-friendly alternatives. Among the most promising solutions is the dry press molded pulp insert—an innovative packaging material known for its recyclability, durability, and versatility. But for businesses with uniquely shaped or delicate products, one important question arises:

Can dry press molded pulp inserts be customized for complex product shapes without sacrificing protection or presentation?

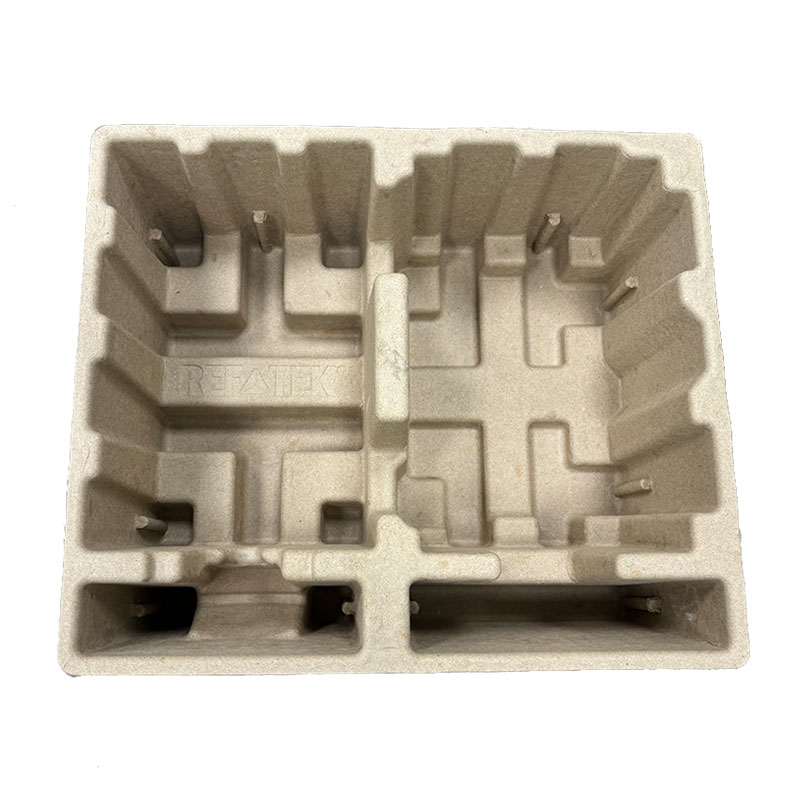

At lvxin, the answer is a confident yes. With advanced design capabilities and precision molding technology, we deliver custom dry molded pulp trays tailored to your exact product specifications—no matter how intricate the shape.

What Is a Dry Press Molded Pulp Insert?

A dry press molded pulp insert is a sustainable packaging component formed by compressing recycled paper fibers into rigid shapes using high-pressure molds. Compared to wet-pressed or thermoformed pulp, dry-pressed inserts offer:

A smoother, more refined surface

Higher strength and dimensional consistency

Efficient production for medium-to-high volumes

These inserts are widely used for packaging:

Electronics

Cosmetics

Medical devices

Consumer goods

Industrial components

Customization for Complex Product Shapes

At lvxin, we specialize in crafting customized molded pulp inserts that accommodate detailed, non-uniform product shapes. Whether you're packaging a multi-component device or an asymmetrical cosmetic bottle, our solutions are designed to protect and present your product effectively.

3D Product Scanning & CAD Modeling

We start with a detailed digital model of your product, using CAD files or 3D scans to map every edge, curve, and indentation. This ensures a perfect fit and secure packaging experience.

CNC Mold Fabrication

Using high-precision CNC machines, we create tooling that reflects your product’s geometry with exact tolerances. This allows the final pulp insert to hold each item securely in place.

Multi-Zone Compression Technology

Our dry press equipment can apply variable pressure across different zones, forming inserts with varying thicknesses, complex contours, and multiple cavities.

Tailored Material Selection

We offer a variety of pulp blends—such as recycled paper, bamboo fiber, and bagasse—to meet your needs for texture, strength, and environmental standards.

Benefits of Custom Dry Molded Pulp Inserts

Product Protection

Custom-fit trays prevent shifting during transport, absorb shocks, and can be enhanced for water or oil resistance if needed.

Environmental Responsibility

Made from renewable resources, these inserts are fully biodegradable, recyclable, and support plastic-free packaging initiatives.

Cost-Effective Scaling

Dry pressing is ideal for medium to large production runs, and the tooling costs are significantly lower than for plastic injection molding.

Enhanced Brand Value

Custom trays provide a polished unboxing experience and can be tailored with surface textures, color matching, and even embossed logos.

Applications Across Industries

Our custom dry press molded pulp inserts are trusted across a wide range of sectors:

Consumer Electronics: For smartphones, chargers, and accessories

Beauty & Cosmetics: For skincare bottles, palettes, and gift sets

Healthcare: For packaging diagnostic tools and medical devices

Industrial Parts: For organizing and protecting precision tools or components

Why Partner with lvxin?

With years of expertise in molded pulp packaging, lvxin offers end-to-end customization services, from prototyping to final production. Our team ensures that each insert not only fits your product but also aligns with your sustainability goals.

We provide:

In-house mold design and development

Rapid prototyping

Reliable production timelines

Custom surface treatment and branding options

Support for global packaging compliance and logistics

Final Thoughts:

As industries shift away from plastics and toward sustainable packaging, dry press molded pulp inserts offer a smart and scalable solution—especially for complex product shapes. With lvxin’s expert support, brands can enjoy the dual benefits of protective design and eco-conscious packaging.

Ready to explore custom molded pulp inserts for your products?

Contact lvxin today to learn how we can turn sustainable materials into a tailored, high-performance packaging solution.