In electronics industry, packaging plays a critical role not only in product protection but also in sustainability and brand differentiation. As environmental concerns intensify, recycled paper pulp packaging emerges as a superior alternative to traditional plastic and foam materials. This shift is driven by the increasing demand for eco-friendly, cost-effective, and highly functional packaging solutions that meet both regulatory standards and consumer expectations. Recycled paper pulp, made from post-consumer and industrial paper waste, offers a unique combination of properties that make it ideally suited for electronics product packaging.

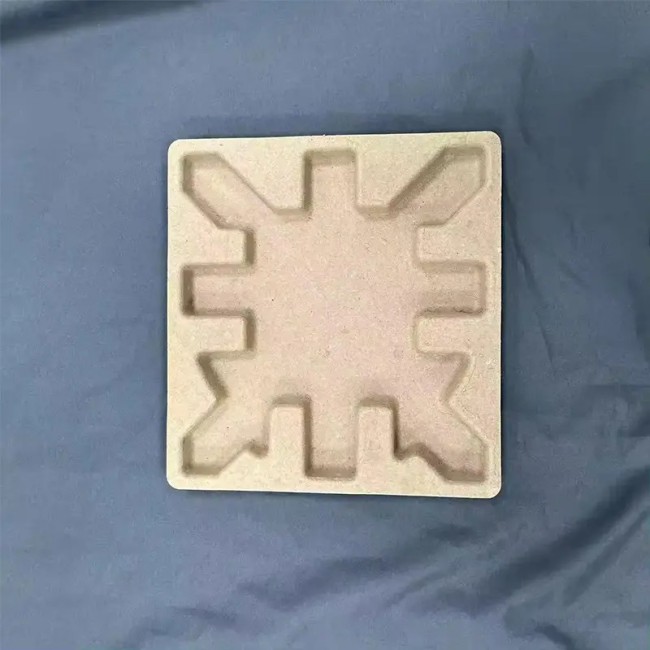

The foremost advantage of recycled paper pulp packaging lies in its excellent protective qualities. Electronics are delicate, requiring packaging that shields them from shocks, vibrations, static discharge, and moisture during transportation and storage. Unlike rigid plastics or fragile foam, recycled pulp packaging can be custom molded to the precise contours of electronic devices, ensuring a snug fit that limits movement and reduces the risk of damage. Its natural fibrous structure provides inherent cushioning, effectively absorbing impact forces and vibrations. Moreover, with appropriate treatment, pulp packaging can mitigate static electricity risks, which is critical for safeguarding sensitive components such as microchips and circuit boards. This level of protection ensures that products arrive intact, reducing returns and enhancing customer satisfaction.

From an environmental perspective, recycled paper pulp stands out as a highly sustainable packaging material. It capitalizes on recycled fibers, diverting paper waste from landfills and reducing the need for virgin raw materials, thereby conserving natural resources and lowering carbon footprints. Compared to plastic packaging, the production of recycled paper pulp consumes less energy and water, resulting in fewer greenhouse gas emissions. Furthermore, the biodegradability and compostability of recycled pulp enable it to break down naturally within weeks under industrial composting conditions, preventing long-term environmental pollution associated with plastic waste. These characteristics align well with global regulatory trends that increasingly restrict single-use plastics and encourage manufacturers to adopt greener packaging practices. Consequently, companies using recycled paper pulp packaging not only comply with environmental laws but also enhance their corporate social responsibility image, gaining favor with eco-conscious consumers and business partners alike.

Economic benefits further reinforce the appeal of recycled paper pulp packaging for electronics. Its raw materials are generally less costly than petroleum-based plastics, and the production processes are efficient and scalable. The lightweight nature of molded pulp packaging translates into lower shipping costs and improved logistics efficiency, an important factor in global electronics supply chains. Additionally, the pulp’s robust structure withstands drops, shocks, and environmental stresses, minimizing product damage and associated costs. Supply chain resilience is another advantage, as recycled pulp is less susceptible to raw material price volatility and geopolitical risks affecting fossil fuel-based packaging materials. This cost-effectiveness and stability make recycled paper pulp an attractive choice for manufacturers seeking to optimize packaging budgets without compromising quality.

Besides its functional and environmental merits, recycled paper pulp packaging offers exceptional design flexibility, allowing electronics manufacturers to create custom inserts, trays, and protective elements tailored precisely to their products. This customization enhances product presentation and consumer experience, making unboxing smoother and more appealing. The natural texture and matte finish of pulp packaging evoke a premium, eco-friendly feel that resonates with modern consumers who prioritize sustainability. Furthermore, the surface of pulp packaging can accommodate high-quality printing and embossing, enabling brands to incorporate logos, instructions, or other visuals directly onto the packaging without additional materials. Such branding opportunities reinforce company identity and differentiate products in a crowded marketplace.

In summary, recycled paper pulp packaging revolutionizes electronics product packaging by seamlessly integrating protection, sustainability, cost efficiency, and aesthetic appeal. As environmental regulations tighten and consumers become increasingly environmentally aware, the adoption of eco-friendly packaging solutions like recycled pulp is not just a trend but a strategic imperative. Electronics manufacturers who embrace recycled paper pulp packaging will benefit from reduced environmental impact, enhanced brand reputation, and improved supply chain efficiency. The future of electronics packaging lies in materials that protect products and the planet alike, and recycled paper pulp stands at the forefront of this transformation.