As companies strive for eco-friendly packaging solutions, dry press molded pulp trays have emerged as a popular choice. Made from recycled paper, these trays offer a sustainable alternative to traditional plastic or foam packaging. But are they truly cost-effective for mass production? Let’s delve deeper into the factors that influence the affordability of dry press molded pulp trays, and why manufacturers are increasingly turning to these trays for large-scale production needs.

What Are Dry Press Molded Pulp Trays?

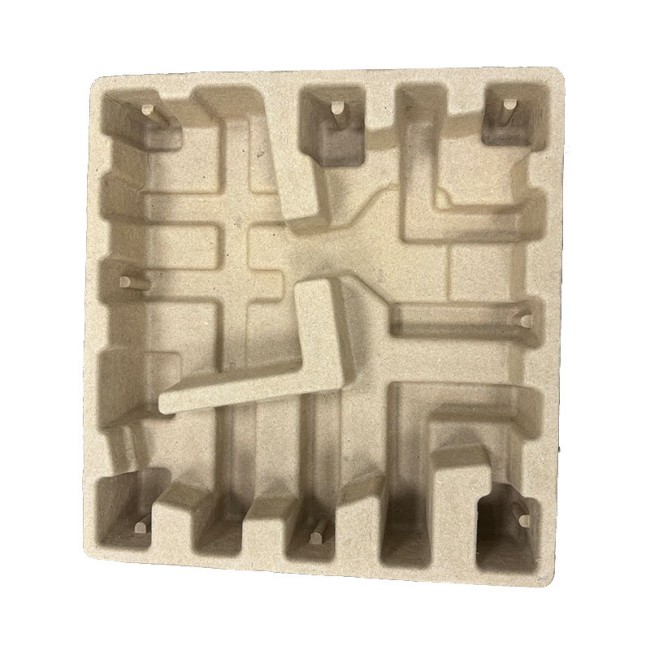

Dry press molded pulp trays are packaging products made by compressing pulp fibers into molds and then drying them to form rigid, lightweight trays. The dry press method uses minimal water and energy, making it more resource-efficient compared to traditional wet-press pulp molding. The result is a durable, biodegradable, and customizable tray that can be tailored to various shapes and sizes, which is especially beneficial for businesses needing specialized packaging for items such as electronics, food, or fragile products.

Key Factors That Impact the Cost-Effectiveness of Dry Press Molded Pulp Trays

The cost-effectiveness of dry press molded pulp trays depends on several important factors:

1. Low Raw Material Costs

One of the main advantages of dry press molded pulp trays is their use of recycled paper as the primary raw material. The availability of recycled paper keeps costs relatively low compared to the production of plastic or foam trays, which require more expensive raw materials and energy. Additionally, using recycled paper supports sustainability efforts, as it helps reduce waste and lowers the need for virgin materials. For manufacturers, this results in a cost-efficient solution, especially when large volumes are involved.

2. Efficient Manufacturing Process

The dry press molding technique is notably efficient. Unlike traditional wet-press molding, which uses a significant amount of water and energy, the dry press process minimizes these resources, leading to lower production costs. The molds used in the dry pressing process are simple and easy to replicate, making it quick and cost-effective for manufacturers to produce large quantities. For mass production, this means a lower per-unit cost, which is a significant advantage in competitive industries.

3. Durability and Reusability

While the upfront cost of dry press molded pulp trays may be slightly higher than plastic alternatives, their durability and environmental benefits make them a cost-effective long-term investment. Unlike plastic trays, which often end up in landfills, pulp trays are biodegradable and compostable, helping companies avoid disposal costs and reduce their environmental impact. Additionally, the durability of these trays can lower the risk of product damage during shipping, which ultimately saves money on returns or replacements.

4. Customizability for Specific Needs

Many manufacturers of dry press molded pulp trays offer customization options, making them ideal for businesses that require trays in unique shapes or with specific compartments. Custom dry press molded pulp trays can be tailored to the exact specifications of a product, ensuring a snug fit and reducing the need for excess packaging material. This customization not only improves efficiency in production but also helps businesses minimize storage and shipping costs by reducing packaging waste.

5. Scalability for Mass Production

Dry press molded pulp trays are highly scalable, making them a great choice for mass production. Once the mold is designed, manufacturers can quickly replicate the process to produce large quantities of trays, benefiting from economies of scale. As production volumes increase, the cost per unit decreases, which makes this type of packaging even more affordable for businesses looking to produce at scale. This scalability ensures that dry press molded pulp trays remain cost-competitive even as demand grows.

6. Environmental Impact and Cost Savings

In today’s environmentally conscious marketplace, sustainability is an important factor in consumer purchasing decisions. Dry press molded pulp trays are made from recycled paper and are fully biodegradable, making them a more environmentally responsible choice compared to plastic packaging. Companies that use these trays can promote their commitment to sustainability, which can lead to enhanced brand loyalty and potentially higher sales. Furthermore, the reduced environmental impact of these trays could translate into lower waste disposal costs and a positive public image, offering long-term financial benefits.

How to Choose the Right Manufacturer for Dry Press Molded Pulp Trays

To get the most out of dry press molded pulp trays, it's essential to choose the right manufacturer. Here are some key considerations:

Quality and Sustainability:Ensure that the dry press mold pulp manufacturer uses high-quality recycled materials and follows eco-friendly production processes. A reliable manufacturer will prioritize sustainability, not only in the materials they use but also in the overall manufacturing process.

Customization and Flexibility: If your products require unique packaging, it’s important to work with a manufacturer that offers custom dry press molded pulp trays. The ability to tailor the design ensures the packaging fits perfectly, reducing material waste and improving efficiency.

Production Capacity and Lead Times: Evaluate the manufacturer’s ability to handle large-scale orders and meet deadlines. Mass production often requires quick turnaround times, so a manufacturer’s production capacity and reliability are essential factors to consider.

Cost-Effectiveness and Pricing: While dry press molded pulp trays are generally cost-efficient, prices can vary depending on factors like customization, order volume, and the complexity of the design. Compare prices from different manufacturers to ensure you're getting the best value for your investment.

Conclusion:

In conclusion, dry press molded pulp trays offer significant advantages in terms of cost-effectiveness, especially for mass production. Their use of low-cost, recycled materials, efficient manufacturing processes, and customizable options makes them a practical and sustainable choice for businesses across various industries. By choosing the right manufacturer, companies can optimize production costs, reduce environmental impact, and create packaging that meets their specific needs. As demand for eco-friendly solutions continues to rise, the cost-effectiveness and versatility of dry press molded pulp trays position them as a smart investment for businesses aiming to stay competitive in today’s market.