As sustainability becomes a global priority, the packaging industry is increasingly adopting eco-friendly materials. Among these, sugarcane bagasse pulp has emerged as a highly popular and sustainable option. Derived from the fibrous residue left after extracting juice from sugarcane, bagasse is biodegradable, renewable, and versatile. It serves as a key material in creating molded pulp trays for a wide array of industries, including food, electronics, and consumer goods. For companies like Lvxin, which specializes in sustainable packaging, choosing the right solutions for sugarcane bagasse pulp trays is crucial to achieving both environmental and functional excellence.

The Advantages of Sugarcane Bagasse Pulp in Packaging

Sugarcane bagasse pulp stands out for its unique properties that make it ideal for packaging solutions:

Eco-Friendliness: Being a byproduct of sugarcane processing, bagasse reduces agricultural waste and provides a sustainable alternative to plastics and Styrofoam. Trays made from molded bagasse pulp are biodegradable and compostable, making them an environmentally responsible choice.

Durability and Versatility: Despite being plant-based, sugarcane bagasse pulp is remarkably sturdy. It offers excellent shock absorption, making it ideal for protective packaging like molded pulp inner packaging trays used in various industries.

Aesthetic Appeal: With its natural texture and ability to be customized, sugarcane bagasse pulp provides a high-end look that appeals to eco-conscious brands and consumers.

Customization Potential: The material is highly adaptable, allowing manufacturers like Lvxin to create packaging solutions tailored to different shapes and sizes, from food containers to sugarcane pulp electronics packaging.

Molded Pulp Tray Sugarcane Bagasse: A Versatile Solution

One of the primary uses of sugarcane bagasse pulp trays is in the food industry. These trays are commonly used for serving meals, storing fresh produce, and packaging takeaway foods. Molded pulp trays made from sugarcane bagasse are resistant to grease, moisture, and heat, ensuring that food remains fresh and uncontaminated. They are particularly popular in environmentally conscious markets where sustainable packaging is a selling point. Lvxin’s molded pulp trays offer an innovative solution to traditional plastic and Styrofoam packaging. With a focus on food safety, Lvxin ensures its trays are free of harmful chemicals, meeting global hygiene standards.

Electronics Packaging: A Growing Market

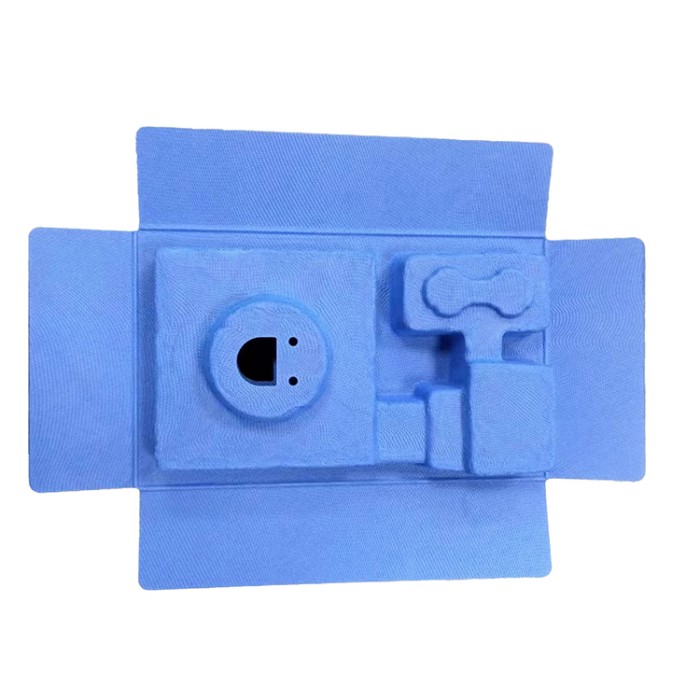

Another area where sugarcane bagasse pulp excels is in electronics packaging. As the demand for sustainable alternatives grows, molded pulp inner packaging trays made from sugarcane pulp are becoming the go-to choice for electronic products.Sugarcane bagasse pulp can be molded into precise shapes, making it ideal for protecting fragile components such as smartphones, laptops, and other gadgets during transportation. These trays are lightweight yet robust, offering a high level of shock absorption. Lvxin has pioneered the use of sugarcane bagasse in electronics packaging, providing custom-molded designs that ensure the safe delivery of products while reducing environmental impact.

Luxury and Consumer Goods Packaging

In addition to food and electronics, sugarcane bagasse pulp trays are gaining traction in the luxury and consumer goods markets. Their clean, natural appearance aligns with the eco-conscious values of high-end brands. Companies are leveraging Lvxin’s expertise to design visually appealing packaging that reflects their commitment to sustainability. From cosmetics to premium gift items, sugarcane bagasse pulp trays provide a sophisticated solution that resonates with modern consumers.

How Lvxin Enhances Sugarcane Bagasse Packaging Solutions

Lvxin, a leading name in sustainable packaging, has developed innovative techniques to maximize the potential of sugarcane bagasse pulp. The company focuses on creating products that combine durability, functionality, and environmental responsibility. Here’s how Lvxin is setting itself apart in the packaging industry:

Advanced Molding Technology: Lvxin uses cutting-edge technology to create highly detailed and customizable molded pulp trays. This allows for precision in packaging design, ensuring that each tray meets the unique needs of its application.

Sustainability Leadership: Beyond using renewable materials, Lvxin employs energy-efficient manufacturing processes that minimize carbon emissions. This commitment to sustainability resonates with clients and end-users alike.

Versatile Product Range: Lvxin’s expertise extends across industries, offering solutions for food packaging, molded pulp inner packaging trays, and sugarcane pulp electronics packaging. The company’s ability to adapt its products to various markets demonstrates its versatility and innovation.

Focus on Quality and Safety: All Lvxin products meet stringent quality standards, ensuring they are safe for direct food contact and capable of protecting fragile electronic components.

The Future of Sugarcane Bagasse Pulp Trays in Packaging

As businesses and consumers increasingly prioritize sustainability, the demand for eco-friendly packaging solutions like sugarcane bagasse pulp trays is set to grow exponentially. With companies like Lvxin leading the charge, the industry is poised to transition away from environmentally harmful materials toward greener alternatives. The versatility of sugarcane bagasse pulp allows it to cater to diverse packaging needs, from foodservice to electronics and beyond. By investing in innovative molding techniques and sustainable practices, Lvxin is not only meeting current market demands but also paving the way for future advancements in eco-friendly packaging.

In conclusion, sugarcane bagasse pulp trays represent the perfect fusion of functionality and sustainability. Their wide-ranging applications, combined with the expertise of manufacturers like Lvxin, make them a leading choice for brands looking to align with green values while maintaining high-quality packaging standards.