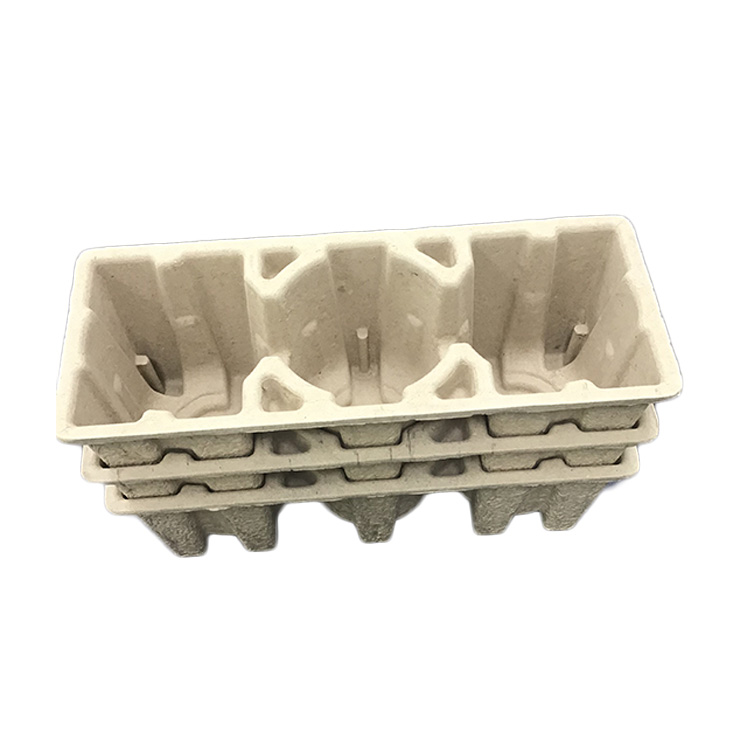

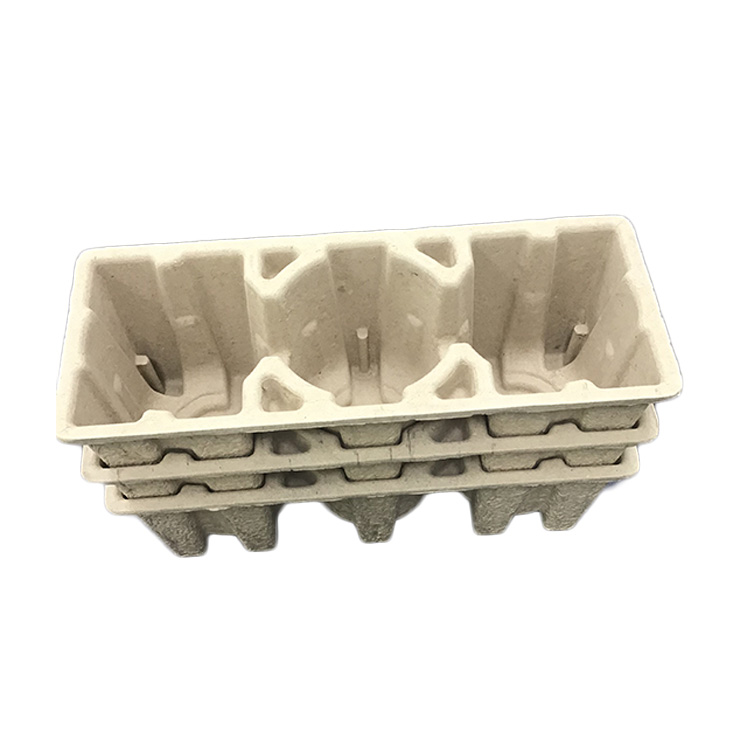

Pulp packaging trays, including wine molded pulp trays, are made from recycled paper pulp that is molded into various shapes and sizes to fit the specific requirements of the product being packaged. These trays offer a lightweight, yet sturdy, solution for holding and protecting wine bottles during transport and storage.In the highly competitive wine industry, packaging is essential for safeguarding the product, elevating its presentation, and ensuring it reaches the consumer in perfect condition. Among the many packaging solutions available, pulp packaging trays, particularly wine molded pulp trays, have become a favored option for bulk packaging. This article will explore why pulp wine bottle packaging is well-suited for bulk needs by examining its advantages, design aspects, and environmental benefits.

Suitability for Bulk Packaging

1. Strength and Durability:

Molded pulp wine trays are designed to be robust and capable of withstanding the rigors of bulk shipping. The molded pulp material is strong enough to hold multiple bottles without compromising its structural integrity.

2. Customization:

One of the key advantages of pulp wine bottle packaging is the ability to customize the trays to fit various bottle sizes and shapes. This customization ensures a snug fit for the bottles, providing optimal protection during bulk packaging and transportation.

3. Lightweight:

The lightweight nature of molded pulp materials makes pulp wine bottle packaging an ideal choice for bulk shipping. This reduces the overall weight of the shipment, leading to lower shipping costs and reduced fuel consumption.

4. Protection:

Molded pulp trays offer excellent protection for wine bottles, with the ability to absorb shocks and vibrations that can occur during transport. This helps to minimize the risk of breakage, a significant concern in bulk packaging.

5. Stackability:

The design of wine molded pulp trays allows for easy stacking, which is essential for efficient use of storage space in warehouses and during transportation.

Benefits of Pulp Wine Bottle Packaging

1. Eco-Friendly:

Pulp packaging is an environmentally responsible choice. Made from recycled materials, these trays are biodegradable and can be recycled again after use, reducing the carbon footprint of the packaging.

2. Cost-Effective:

Compared to other packaging materials, pulp wine bottle packaging offers a cost-effective solution without compromising on quality and protection.

3. Branding Opportunities:

The surface of molded pulp trays can be easily printed with brand logos, colors, and designs, providing an opportunity for brand visibility and marketing.

4. Moisture Resistance:

Molded pulp materials can be treated to provide a level of moisture resistance, which is particularly important for protecting wine bottles during storage and transport.

5. Versatility:

Pulp wine bottle packaging is not only limited to simple trays. They can be designed in various forms, including multi-bottle carriers, single bottle protectors, and even integrated with other packaging components.

The environmental benefits of using pulp wine bottle packaging cannot be overstated. By choosing a biodegradable and recyclable material, wineries can demonstrate their commitment to sustainability and reduce the environmental impact of their packaging.Molded pulp wine trays are indeed suitable for bulk packaging, offering a combination of strength, durability, customization, and environmental responsibility. As the demand for sustainable packaging solutions grows, pulp wine bottle packaging stands out as an excellent choice for wineries looking to protect their products, reduce their environmental footprint, and enhance their brand's image. By considering the various benefits and design options, wine producers can make an informed decision that aligns with their business goals and values.