In today's world, where environmental sustainability is at the forefront of global consciousness, innovative solutions are emerging to tackle the challenges of packaging waste. Among these solutions, the rise of pulp molded trays stands out as a beacon of eco-friendly innovation. Through the ingenious use of recycled materials and efficient manufacturing processes, pulp molded trays are revolutionizing the packaging industry, offering a sustainable alternative to traditional packaging methods.

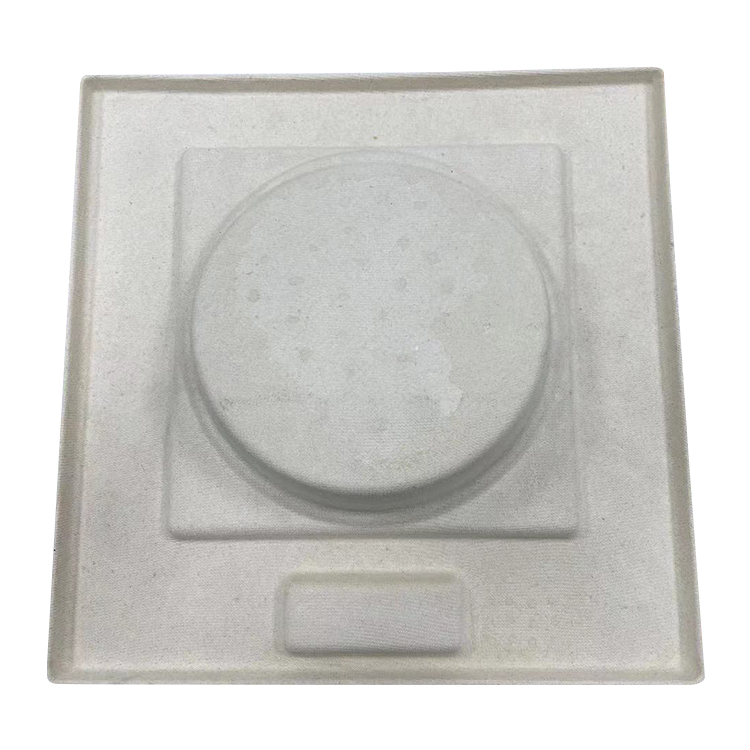

At the heart of this revolution lies the concept of pulp molding. Pulp molding, also known as molded pulp or molded fiber, involves the conversion of recycled paper and cardboard into sturdy packaging products through a process of molding and drying. This technique not only minimizes waste by repurposing materials that would otherwise end up in landfills but also reduces the need for virgin materials, thus conserving natural resources.One of the most common applications of pulp molded trays is in the packaging of fragile items such as electronics, glassware, and consumer goods. Unlike conventional packaging materials like plastic or polystyrene, which are derived from non-renewable resources and contribute to pollution, molded pulp trays offer superior protection while being biodegradable and compostable. This makes them an ideal choice for companies looking to enhance their environmental credentials and reduce their carbon footprint.

Packaging box trays made from molded pulp are not only environmentally friendly but also versatile and customizable. Manufacturers can tailor the design, size, and shape of the trays to fit the specific requirements of their products, ensuring optimal protection during transit while minimizing excess packaging. Moreover, pulp molded trays can be easily branded and printed with logos, labels, and other marketing messages, enhancing product visibility and brand recognition.In addition to their environmental and functional benefits, molded pulp tray packaging offers significant cost savings for businesses. The use of recycled materials reduces raw material costs, while the lightweight nature of pulp trays reduces shipping expenses and carbon emissions associated with transportation. Furthermore, many regions offer incentives and subsidies for companies that adopt sustainable packaging practices, further incentivizing the switch to pulp molded trays.

As consumer demand for sustainable products continues to grow, businesses across industries are recognizing the importance of adopting eco-friendly packaging solutions. Pulp molded trays provide an effective way for companies to align with consumer values and demonstrate their commitment to environmental responsibility. By making the switch to molded pulp packaging, businesses can differentiate themselves in the market, attract environmentally conscious consumers, and contribute to the global effort to combat climate change.The rise of pulp molded trays represents a paradigm shift in the packaging industry, signaling a departure from the era of single-use plastics and excessive packaging waste. As more companies embrace this eco-friendly innovation, the benefits will extend beyond environmental conservation to include economic savings, enhanced brand reputation, and a healthier planet for future generations.

At last, the adoption of pulp molded trays is not just a trend but a necessity in today's world. With their sustainable materials, customizable designs, and cost-saving advantages, molded pulp tray packaging offers a win-win solution for businesses and the environment alike. As we continue to seek ways to reduce our ecological footprint, pulp molded trays stand out as a shining example of eco-friendly innovation in the packaging industry.