In the realm of modern manufacturing, the quest for sustainability has become paramount. With environmental concerns looming large, industries across the globe are seeking eco-friendly alternatives to traditional materials and processes. Among these alternatives, molded pulp trays have emerged as a frontrunner, offering a versatile and environmentally responsible solution for packaging needs. Molded pulp tray manufacturers play a pivotal role in this narrative, spearheading the movement towards sustainable packaging solutions.

1. Understanding Molded Pulp Trays

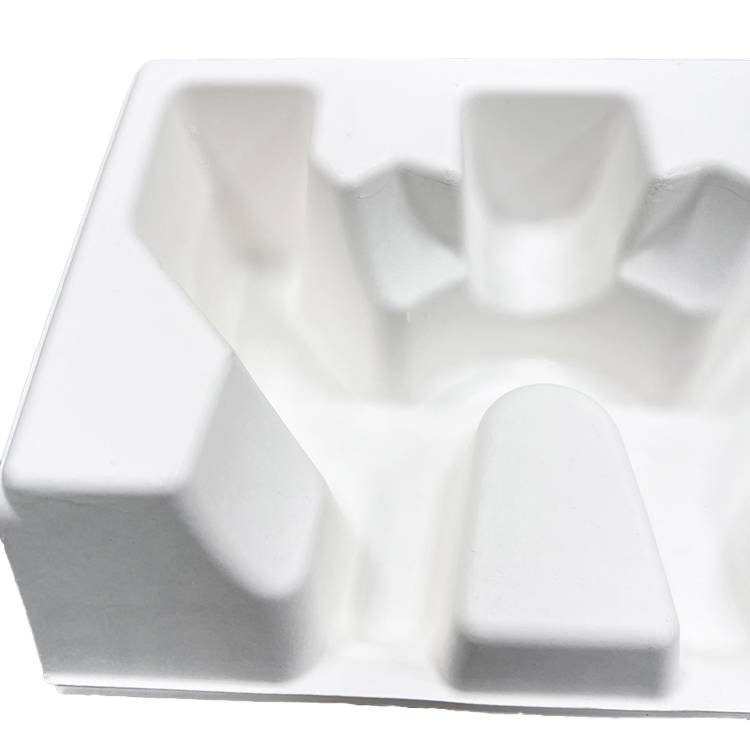

Molded pulp trays, also known as moulded pulp trays, are crafted from a blend of recycled paper, cardboard, or other fibrous materials. These materials are processed into a pulp, molded into various shapes, and then dried to create sturdy and resilient trays. The resulting products are lightweight, yet robust enough to offer ample protection for a wide array of goods.

2. The Rise of Sustainable Packaging

In recent years, there has been a significant shift towards sustainable packaging solutions, driven by both consumer demand and corporate responsibility. As awareness about environmental issues continues to grow, businesses are increasingly turning to molded pulp trays for their packaging needs. These trays offer several key advantages:

Biodegradability: Molded pulp trays are fully biodegradable, meaning they break down naturally over time, posing minimal harm to the environment.

Recyclability: The materials used in molded pulp trays are often sourced from recycled sources and can be recycled again after use, contributing to a circular economy.

Renewable Resources: Unlike plastic packaging, which relies on finite fossil fuels, molded pulp trays are made from renewable resources such as paper and cardboard.

3. The Role of Molded Pulp Tray Manufacturers

Molded pulp tray manufacturers play a crucial role in driving the adoption of sustainable packaging solutions. These companies specialize in the design, production, and distribution of molded pulp trays, catering to a diverse range of industries and applications. Their expertise lies not only in crafting high-quality trays but also in innovating new designs and production techniques to meet evolving market demands.

4. Innovation and Customization

One of the key strengths of molded pulp tray suppliers is their ability to innovate and customize solutions to suit specific requirements. Whether it's designing trays for electronics, food and beverage, or healthcare products, manufacturers can tailor their offerings to meet the unique needs of their clients. This flexibility allows businesses to benefit from sustainable packaging solutions without compromising on functionality or aesthetics.

5. Advantages of Pulp Tray Packaging

The adoption of pulp tray packaging offers several benefits across various industries:

Product Protection: Molded pulp trays provide excellent cushioning and protection for fragile or delicate items during transportation and storage.

Brand Image: Choosing sustainable packaging solutions can enhance a company's brand image, appealing to eco-conscious consumers and stakeholders.

Regulatory Compliance: Molded pulp trays often meet stringent regulatory requirements for food safety and product protection, providing peace of mind to manufacturers and consumers alike.

Environmental Impact:

By opting for molded pulp tray packaging, businesses can significantly reduce their environmental footprint. The use of recycled materials, coupled with the biodegradability of pulp trays, helps mitigate the impact of packaging waste on landfills and ecosystems. Additionally, the energy and water consumption associated with pulp tray production are typically lower than traditional packaging materials, further reducing environmental strain.

As the demand for sustainable packaging solutions continues to rise, molded pulp tray manufacturers are poised to play an increasingly significant role in shaping the future of packaging. By offering eco-friendly alternatives to traditional materials, these companies are not only meeting the needs of their clients but also contributing to a more sustainable and resilient planet. As consumers and businesses alike prioritize environmental stewardship, the importance of molded pulp trays in the packaging industry is only set to grow. Through innovation, customization, and a commitment to sustainability, molded pulp tray manufacturers are crafting a brighter, greener future for packaging solutions worldwide.