In recent years, there has been a significant shift towards sustainable packaging solutions across various industries. Molded pulp packaging, also known as molded fiber packaging, has emerged as a popular choice due to its eco-friendly nature and versatility. From egg cartons to protective packaging for electronics, molded pulp offers a sustainable alternative to traditional materials like plastic and foam. In this article, we'll explore the process of making molded pulp packaging, from raw materials to finished products.

1. Raw Material Selection:

The first step in making molded pulp packaging is selecting suitable raw materials. Molded pulp is typically made from recycled paper and cardboard, although some manufacturers may use other plant-based fibers. The quality and composition of the raw materials can affect the strength, appearance, and overall performance of the final packaging.

2. Pulping:

Once the raw materials are selected, they undergo a pulping process to break down the fibers and create a pulp mixture. This process involves shredding the paper or cardboard into small pieces and mixing them with water to form a slurry. The slurry is then heated and agitated to further break down the fibers and create a uniform pulp mixture.

3. Molding:

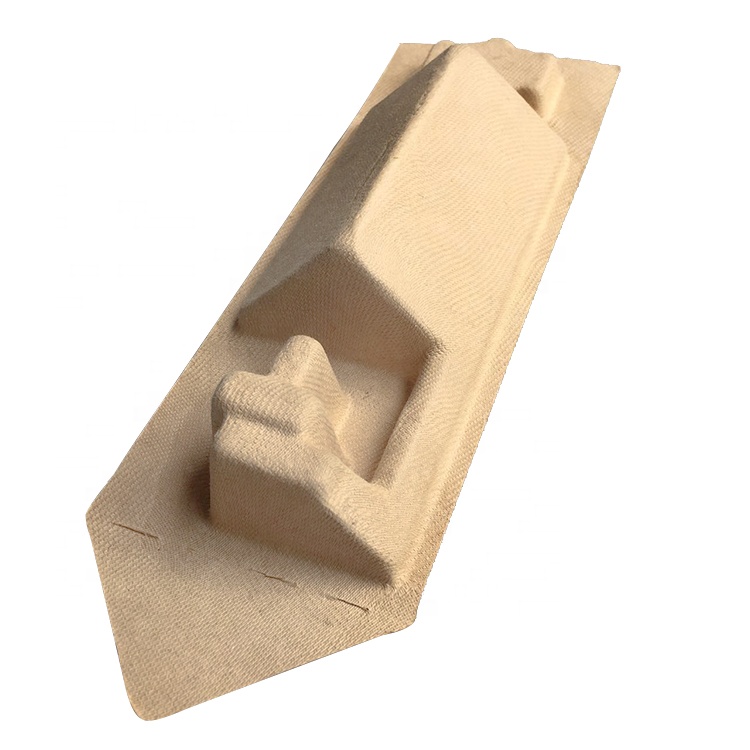

After pulping, the pulp mixture is poured into molds or trays designed to the desired shape and size of the packaging. These molds can be made from various materials, including metal, plastic, or silicone, depending on the specific requirements of the packaging. The pulp mixture is evenly distributed in the molds, ensuring uniform thickness and density in the final product.

4. Pressing:

Once the molds are filled, they undergo a pressing process to remove excess water and compact the pulp fibers. This can be done using hydraulic presses or vacuum-assisted molding machines, depending on the production scale and equipment available. Pressing helps to create strong and durable packaging with consistent thickness and density.

5. Drying:

After pressing, the molded pulp packaging is transferred to drying chambers or conveyor belts to remove any remaining moisture. The packaging is dried at controlled temperatures to ensure uniform drying and prevent deformation. Drying times can vary depending on factors such as the thickness of the packaging and ambient humidity.

6. Finishing:

Once dry, the moulded paper pulp undergoes finishing processes to enhance its appearance and functionality. This may include trimming to remove any rough edges or excess material, as well as additional treatments such as coating or printing for branding and customization. Finishing processes help to ensure that the packaging meets the desired specifications and quality standards.

Advantages of Molded Pulp Packaging:

Molded pulp packaging offers numerous advantages over traditional packaging materials:

Eco-Friendly: Molded pulp is made from recycled materials and is fully biodegradable and compostable, making it an environmentally friendly choice.

Versatility: Molded pulp packaging can be molded into various shapes and sizes to accommodate a wide range of products, from delicate electronics to food items.

Protection: Molded pulp packaging provides excellent cushioning and protection for products during shipping and handling, reducing the risk of damage or breakage.

Cost-Effective: Molded pulp packaging is often more cost-effective than other packaging materials, offering manufacturers a sustainable solution without compromising on quality.

In conclusion, molded pulp packaging offers a sustainable and effective solution for a wide range of packaging needs. By following the steps outlined above, manufacturers can create high-quality packaging that is both eco-friendly and functional. As consumer demand for sustainable packaging continues to grow, molded pulp is poised to play an increasingly important role in the packaging industry. By embracing this versatile and eco-friendly material, manufacturers can reduce their environmental footprint while delivering products that are safe, secure, and sustainable.