1. Raw Material Selection:

The journey towards creating molded pulp inserts begins with a conscious choice of raw materials. Recycled paper and cardboard, sourced from post-consumer and post-industrial waste, form the foundation of these eco-friendly inserts. This environmentally responsible selection sets the stage for a packaging solution that not only safeguards products but also minimizes the ecological footprint.

2. Pulping Process:

The selected recycled paper undergoes a meticulous pulping process. This involves breaking down the paper into individual fibers by soaking it in water and utilizing mechanical agitation. The outcome is a pulpy slurry that becomes the fundamental material for molded pulp inserts. This stage showcases the transformative power of repurposing waste into a valuable and sustainable resource.

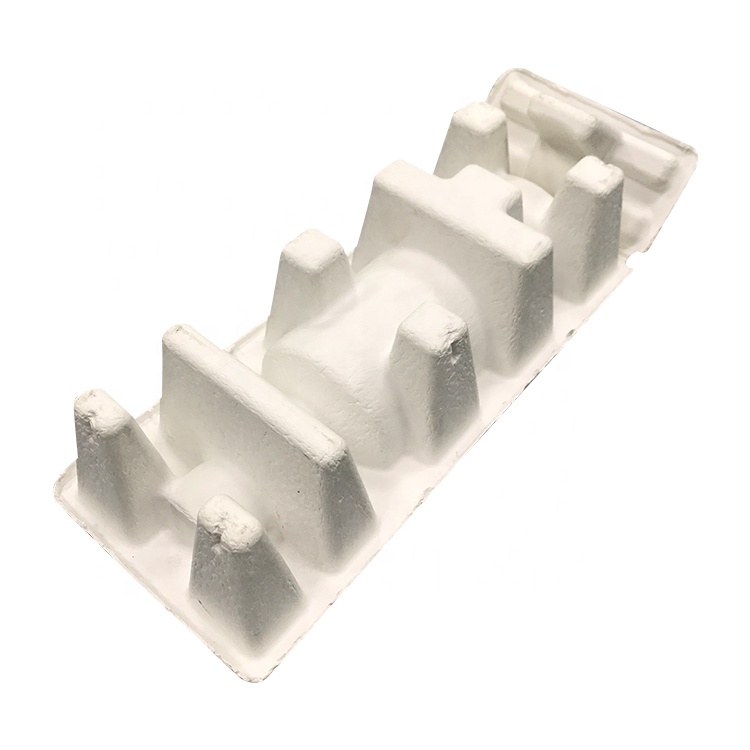

3. Molding Magic:

The pulped material takes shape through the molding process, either by pouring it into molds or utilizing specialized machinery. This step is pivotal as it defines the structure and form of the final molded pulp inserts. The versatility of molds allows for customization, enabling the inserts to cater to various product shapes and sizes. Molding transforms recycled fibers into protective and functional packaging components.

4. Drying and Stabilizing:

Following molding, the inserts undergo a pressing and drying phase. Excess water is removed through pressing, and the drying process solidifies the structure. This meticulous drying phase ensures that the molded pulp inserts maintain their integrity and strength, contributing to their effectiveness in providing protection during transportation and handling. The result is a durable and resilient packaging solution.

5. Biodegradability and Beyond:

One of the standout features of molded pulp inserts is their inherent biodegradability. These inserts are designed to naturally decompose over time, aligning with the principles of a circular economy. The eco-friendly nature of molded pulp inserts not only reduces environmental impact but also caters to the growing consumer demand for sustainable packaging solutions. Beyond their protective role, molded pulp inserts enhance the overall consumer experience by communicating a commitment to environmental responsibility.

In conclusion, the process of crafting molded pulp inserts unfolds as a sustainable journey from recycled materials to a functional and customizable packaging solution. From the conscious selection of raw materials to the transformative pulping and molding processes, each step contributes to the creation of inserts that not only protect products but also embody the principles of sustainability and responsible resource utilization. Molded pulp inserts stand at the forefront of eco-friendly packaging, illustrating the harmonious integration of innovation and environmental stewardship in the modern packaging industry.