With sustainability becoming a central pillar in global manufacturing, the pressure on electronics brands to rethink their packaging strategy is intensifying. From smart locks and routers to wearables and IoT devices, more manufacturers are seeking alternatives to plastic and foam. One increasingly popular solution is dry pressed pulp packaging—an environmentally friendly packaging material that offers both protection and biodegradability. But how sustainable is it really? And is it practical enough to replace traditional packaging for electronic products?

Let’s dive deeper.

What Is Dry Pressed Pulp Packaging?

Dry pressed pulp packaging, also known as dry-molded fiber packaging, is a rigid, paper-based material made by compressing pulp—typically from recycled paper, cardboard, or agricultural fibers—into precise shapes under heat and pressure. Unlike wet-molded pulp, dry pressing delivers a smoother finish and tighter tolerances, making it suitable for delicate and high-end products.

It’s commonly used in:

-

Consumer electronics (e.g. smart locks, earbuds, routers)

-

Medical devices

-

Cosmetics

-

Industrial tools and equipment

Its ability to protect fragile goods while aligning with green packaging goals makes it an increasingly attractive option for electronics brands.

Why Is Molded Pulp for Electronics Considered Sustainable?

1. Made from Renewable and Recycled Resources

Dry pressed pulp is typically produced from:

-

Recycled paper and cardboard waste

-

Bagasse (sugarcane residue)

-

Bamboo or wood pulp from sustainably managed forests

These raw materials are abundant, renewable, and often derived from post-consumer waste, significantly reducing the environmental impact compared to petroleum-based plastics or foams.

2. Fully Biodegradable and Compostable

One of the standout features of molded fiber packaging is its end-of-life sustainability. Depending on conditions, it decomposes naturally within 90 to 180 days in soil or compost, returning to nature without leaving microplastics or toxic residues. This directly supports circular economy goals and helps reduce landfill pressure.

3. Energy and Water Efficient Production

Compared to plastic thermoforming, the dry pressing process consumes less water and energy. While the initial mold creation requires some investment, mass production is efficient and scalable—especially when aligned with solar-powered or low-waste manufacturing facilities.

4. Compliance with Global Packaging Standards

Governments and retailers are implementing strict regulations to reduce plastic use. Dry pressed pulp packaging helps electronics manufacturers comply with:

-

EU Packaging and Packaging Waste Directive

-

RoHS and REACH regulations

-

California Plastic Waste Reduction regulations

-

FSC or PEFC-certified packaging requirements

Using eco-friendly electronic packaging isn’t just ethical—it’s becoming mandatory in many markets.

Performance in Real-World Electronics Packaging

Can molded pulp really protect electronics? The answer is yes—with the right design.

Mechanical Protection

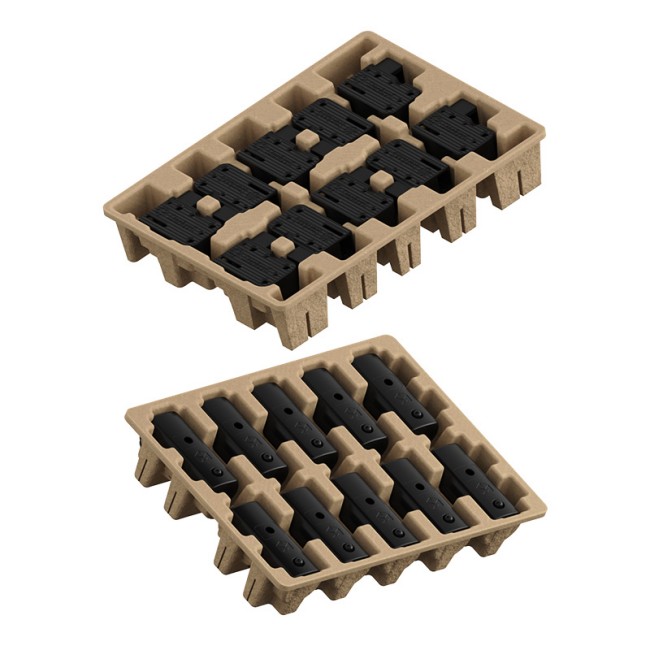

Dry pressed molded fiber trays can be engineered to absorb shocks, resist pressure, and protect products from movement during transit. For smart locks, mobile devices, and circuit boards, well-designed pulp trays offer comparable protection to plastic clamshells or foam inserts.

Thermal and Humidity Resistance

Although uncoated pulp is naturally absorbent, water-resistant coatings or lamination can enhance durability in humid or high-temperature environments. Many suppliers now offer pulp trays with bio-based coatings that remain compostable.

Custom Fit and Structural Precision

Thanks to CNC-cut molds, pulp packaging can be produced with high precision, accommodating even uniquely shaped devices. Electronics brands can design trays with:

-

Internal support ribs

-

Embedded cable channels

-

Multi-layer inserts for accessories

-

Separate compartments for instructions, chargers, or tags

The result is a clean, secure, and organized unboxing experience—without plastic.

Growing Demand in the Smart Lock Industry

An increasing number of smart lock manufacturers are adopting sustainable molded fiber packaging as part of their ESG and brand elevation strategies. Here's why:

-

Brand Perception: Eco-conscious packaging reinforces a high-tech, responsible image

-

Logistics Efficiency: Stackable trays reduce shipping volume and breakage rates

-

Cost Optimization: Once tooling is in place, pulp packaging offers excellent ROI

-

Global Distribution Compliance: Easier export to markets with plastic restrictions

-

Consumer Preference: 72% of tech buyers prefer sustainable packaging when given the choice (based on a 2024 Nielsen study)

Brands that embrace pulp-based packaging now are not only future-proofing—they’re also differentiating.

Challenges and Limitations

Despite its many benefits, dry pressed pulp packaging isn’t without limitations:

Moisture Sensitivity

Uncoated trays may absorb moisture, which is not ideal for highly sensitive electronics unless paired with desiccants or sealed inner cartons.

Upfront Mold Cost

Initial tooling fees for customized pulp trays can be higher than standard plastic inserts, although this is usually offset over time by volume savings and regulatory advantages.

Limited Color and Finish Options

While pulp can be tinted or coated, it lacks the gloss and aesthetic flexibility of plastic unless premium treatments are applied. However, the natural, matte aesthetic is often seen as a premium look in eco-focused branding.

Looking Ahead: The Role of Sustainable Molded Fiber in Electronics

As carbon reporting, green certifications, and plastic-free mandates tighten globally, molded pulp for electronics is poised for massive growth. Leading packaging manufacturers are innovating with:

100% biodegradable coatings

Water-repellent nano-treatments

Hybrid designs that combine pulp with paperboard sleeves or reusable inserts

Fully recyclable molded fiber with embedded RFID/NFC labels

Forward-thinking electronics brands that align packaging with sustainability trends today will not only reduce environmental impact, but also future-proof their products in tomorrow’s regulatory and market environment.

Conclusion:

So, how sustainable is dry pressed pulp packaging for electronic products?

In short, it is one of the most practical and impactful green packaging solutions currently available for the electronics industry. By balancing functionality, cost-efficiency, and environmental performance, molded pulp offers a compelling alternative to plastic—especially for products like smart locks, accessories, routers, and small devices. For electronics manufacturers aiming to reduce waste, enhance customer perception, and meet global sustainability standards, dry pressed pulp packaging is not just an option—it’s a strategic imperative.