Molded fiber products are becoming increasingly popular across industries. From packaging materials to protective trays, the versatility of molded pulp offers numerous applications. However, the ability to customize the color of these molded fiber products is an essential feature that enhances product appeal and aligns with branding goals. For businesses and manufacturers, partnering with the right color mould pulp supplier becomes critical in achieving the perfect balance of sustainability, functionality, and design. In this article, we explore the importance of custom color mould pulp, methods of achieving custom colors, and the benefits of working with a professional custom color mold pulp supplier.

The Growing Significance of Molded Fiber Products

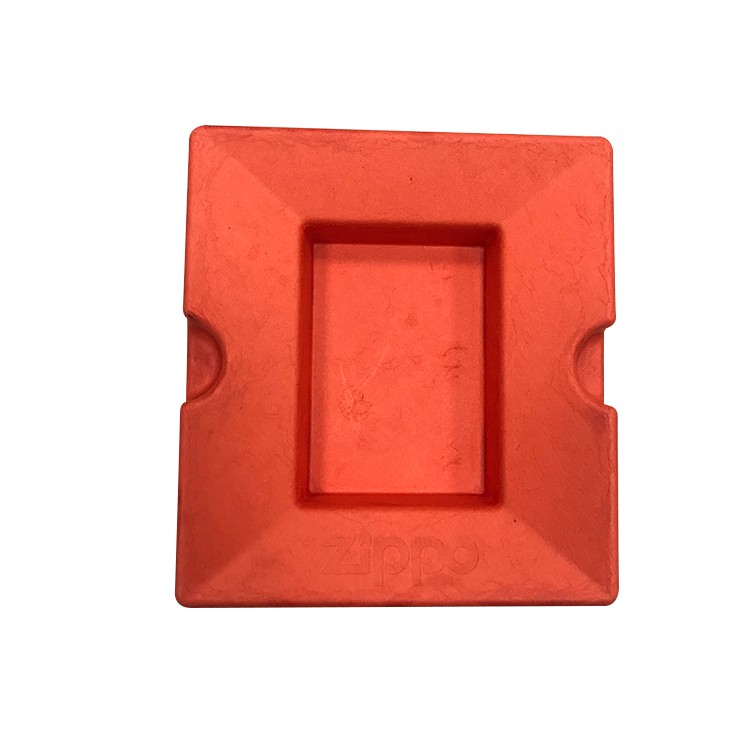

Molded fiber products are made primarily from recycled paper pulp, which makes them an eco-friendly alternative to plastic and other non-biodegradable materials. Their biodegradability, recyclability, and compostability have led to widespread adoption across various sectors such as consumer goods packaging, food containers, and industrial packaging solutions. As companies strive to meet sustainability goals, the demand for custom color molded pulp has surged, providing brands with a unique opportunity to combine eco-friendliness with personalized design. By introducing customized colors into the equation, businesses are able to further differentiate their products, appeal to consumers’ aesthetic preferences, and even communicate brand values through color psychology.

Why Custom Color Mold Pulp is Essential for Modern Products

Customizing the color of molded fiber products is a critical step for businesses aiming to stand out in a crowded marketplace. The choice of color not only enhances the visual appeal of the product but also influences consumer perception and purchasing behavior. Below are some compelling reasons why custom color molded pulp has become so essential:

1. Strengthening Brand Identity

Color plays a significant role in branding. Whether it’s through the use of bold, vibrant hues or subtle, sophisticated tones, custom-colored molded fiber products allow businesses to align their packaging or products with their unique brand identity. For companies in sectors like food, cosmetics, and luxury goods, custom colors can create a memorable impression that resonates with customers. By choosing the right colors, businesses can convey specific brand messages—such as trust, sustainability, luxury, or energy—ensuring that the product aligns with the emotional triggers of its target audience. Working with a reliable custom color mould pulp supplier ensures that the right color match is achieved consistently.

2. Meeting Consumer Preferences

Customized colors are not just about aesthetics—they cater to consumer preferences as well. Different markets or regions may favor particular colors, whether due to cultural reasons or industry trends. Customizing colors enables businesses to meet these specific demands, creating products that feel more tailored and relevant to local consumer bases.

3. Product Differentiation

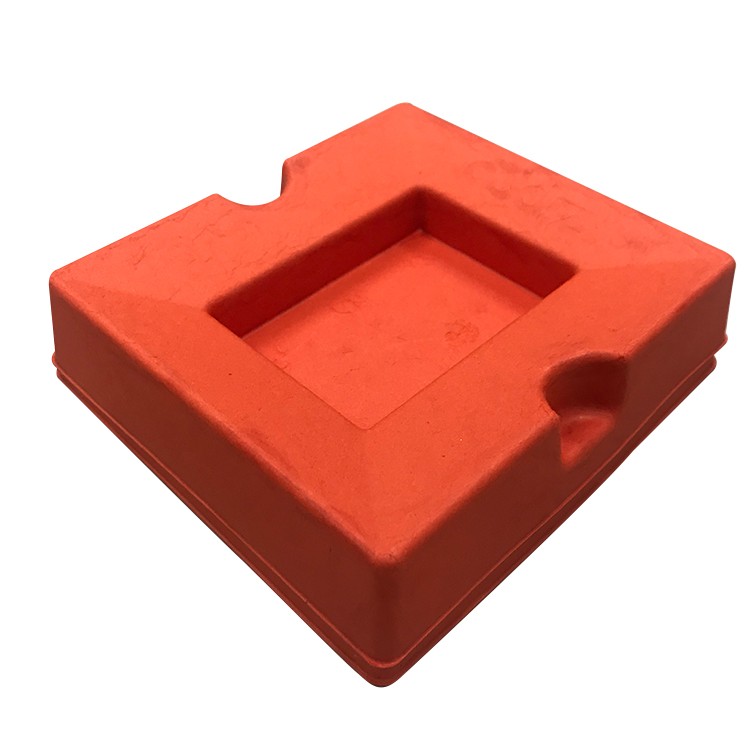

In a competitive landscape, product differentiation is key. Customized colors help brands differentiate their products from competitors. Unique colors make products more recognizable, adding to their shelf appeal. Whether it’s through the custom color mold pulp technique or surface coatings, adding distinctive colors ensures that molded fiber products are not just functional but also eye-catching.

How Custom Colors are Achieved in Molded Fiber Products

Achieving custom colors in molded fiber products requires specific techniques that ensure durability, consistency, and aesthetic quality. The most common methods for achieving vibrant and long-lasting colors include:

1. Dyeing the Pulp

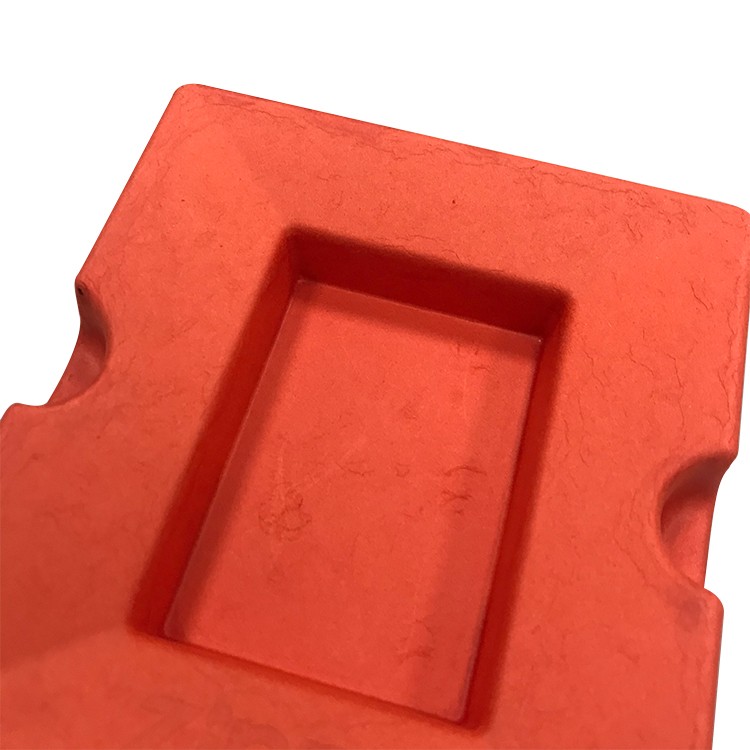

One of the most popular methods of coloring molded fiber products is by adding dyes directly to the molding pulp before the product is formed. This technique ensures that the color is fully integrated into the pulp, which makes it resistant to fading or wear over time. Using eco-friendly, non-toxic dyes, a color mould pulp supplier can offer a wide range of hues, allowing businesses to select the ideal color for their needs.

This method is best for large batches of molded products such as packaging materials, protective trays, and food containers where consistency and durability are essential. The color penetrates deep into the fibers, ensuring uniformity throughout the product.

2. Surface Coatings and Finishes

For products that require more intricate designs, surface coating is an effective technique for achieving custom colors. This process involves applying a colored finish to the surface of the molded fiber product, offering a wider range of aesthetic possibilities. Surface coatings can provide different textures, from matte to glossy finishes, and can even be used to create patterns, logos, or images on the product.

This method is ideal for products that need to stand out or convey premium quality, such as luxury packaging or custom promotional items. While the color does not penetrate the material as deeply as dyeing, surface coatings allow for detailed customization and can be applied using techniques such as spraying, dipping, or brushing.

3. Printing and Branding

Printing allows for even greater design flexibility and color customization. Flexographic printing, digital printing, and screen printing methods are often used to apply multi-color logos, designs, or branding elements to molded fiber products. Printing enables companies to create unique, visually striking designs that help reinforce brand identity and make products more memorable.

For packaging companies and consumer goods brands, printing on molded pulp products offers the opportunity to incorporate multicolor graphics or intricate designs. A custom color mold pulp supplier that offers printing services can provide exceptional quality prints that won’t wear or fade easily.

4. Heat Stamping and Foil Application

For premium and luxury molded fiber products, techniques like foil stamping and heat pressing are used to add metallic or reflective colors to the product's surface. This method creates a high-end look and is commonly applied to luxury packaging and limited-edition items where the product's appearance is crucial to its appeal.

These methods help add elegance and sophistication to molded fiber products, setting them apart in industries where aesthetics play a key role in consumer decision-making.

Benefits of Custom Color Mold Pulp for Businesses

Customizing the color of molded fiber products offers numerous advantages for both manufacturers and end consumers. Let’s explore some of the key benefits:

1. Enhanced Visual Appeal and Brand Recognition

Custom colors help products stand out in a crowded market, making them more likely to grab consumer attention. Whether it’s through the use of bold or subtle hues, colors play a critical role in visual appeal, making products more attractive and memorable. For businesses, the ability to customize colors also reinforces brand recognition, ensuring that their products are instantly identifiable.

2. Increased Product Perceived Value

Products with custom colors often appear more refined and premium, which can increase their perceived value. Consumers associate unique or vibrant colors with higher quality, and this can justify higher price points. As a result, custom colors help businesses cater to premium markets, ensuring that their products feel exclusive and luxurious.

3. Versatility and Market Adaptability

Customization is not just about appearance—it's about meeting diverse market needs. By offering custom color mould pulp, businesses can tailor their products to suit different industries and consumer preferences. Whether serving different regions, market segments, or cultural preferences, custom colors provide versatility that helps businesses stay ahead in the competitive landscape.

4. Environmentally Responsible Solutions

The techniques used to achieve custom colors in molded fiber products are often environmentally friendly. Many suppliers offer eco-conscious dyes and coatings, helping businesses maintain their sustainability goals while achieving the desired aesthetic. By opting for custom color molded pulp, companies contribute to reducing plastic waste and promoting a more sustainable future.

Conclusion:

Customized colors for molded fiber products are essential for businesses looking to differentiate their offerings, strengthen brand identity, and meet consumer expectations. Working with a trusted color mould pulp supplier ensures that companies can achieve vibrant, durable, and high-quality color effects while maintaining the eco-friendly benefits of molded fiber materials. From dyeing to surface coatings and printing, there are numerous techniques available to add custom colors to molded fiber products, offering unmatched flexibility and creative potential. As the demand for sustainable and visually appealing solutions grows, custom color mold pulp will continue to play a pivotal role in the success of molded fiber products across industries.

If you want to read more information about how to boost traffic on your Website just visit -->http://www.pulptray.com