In today’s environmentally conscious world, businesses and consumers alike are seeking sustainable packaging solutions. One innovative and eco-friendly option is dry press molded pulp trays. But as companies have unique requirements for packaging, the question arises: can dry press molded pulp trays be customized to meet specific needs? The answer is a resounding yes. Let’s explore how customization works and why choosing a reputable dry press molded pulp manufacturer is crucial.

1. Understanding Dry Press Molded Pulp Trays

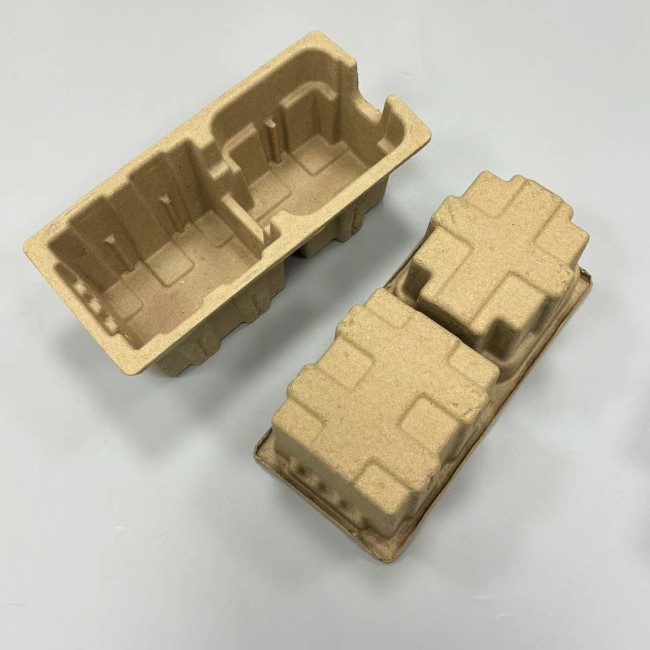

Dry press molded pulp trays are crafted from natural fibers, primarily recycled paper and other renewable materials. Through a process known as dry pressing, these fibers are molded into rigid, durable trays that can safely hold various items. This makes them a sustainable alternative to plastic and foam packaging, reducing the overall environmental impact. A dry pressing paper pulp tray is biodegradable and compostable, appealing to businesses aiming to enhance their green credentials.

2. The Customization Process

Customization of dry press molded pulp trays begins with understanding the client’s specific requirements. Dry press molded pulp manufacturers typically follow these steps:

Design Consultation: Manufacturers work with clients to create a custom design that fits the product’s dimensions, weight, and protection needs. This step involves creating a 3D model or prototype to ensure the fit and functionality of the tray.

Mold Creation: Once the design is approved, a custom mold is created. This mold serves as the template for the trays and ensures consistency across production.

Material Selection: While the primary materials remain eco-friendly fibers, manufacturers can choose specific blends that enhance certain properties, such as added strength or moisture resistance.

Production and Quality Control: The customized trays are mass-produced using dry pressing methods. Quality control measures are taken to ensure each tray meets the client's standards and holds up under expected use conditions.

3. Advantages of Customizing Dry Press Molded Pulp Trays

Customizing dry press molded pulp trays offers multiple benefits to businesses:

Perfect Fit for Products: Custom trays can be tailored to the exact shape and size of the product, providing better protection during shipping and handling.

Enhanced Branding: Customized trays can feature logos, brand colors, or unique designs that reinforce brand identity.

Optimized Functionality: Special features, such as compartments or dividers, can be added to improve the tray’s usability and functionality.

Improved Customer Experience: A tailored tray not only secures the product but also enhances the unboxing experience, leading to greater customer satisfaction.

4. Why Work with Reputable Dry Press Molded Pulp Manufacturers?

Choosing the right dry press molded pulp manufacturer is essential for achieving high-quality, customized trays. Established manufacturers have the expertise, equipment, and capacity to deliver on complex design requirements. Here’s what to look for when selecting a manufacturer:

Experience and Portfolio: Look for manufacturers with a proven track record in producing customized dry press molded pulp trays. A portfolio showcasing their work across various industries can indicate their capability.

Sustainable Practices: Ensure the manufacturer uses eco-friendly and sustainable production methods that align with your company’s values.

Customer Service and Support: A reliable manufacturer will offer ongoing support, from design consultation to post-production inquiries.

5. Applications of Custom Dry Press Molded Pulp Trays

Custom dry press molded pulp trays are used in a wide array of industries:

Electronics: Tailored trays offer secure housing for sensitive electronic components, reducing damage during transportation.

Food Packaging: Custom trays can be designed for direct food contact, making them ideal for meal kits and fresh produce.

Medical Supplies: Specialized compartments in the trays ensure the safe storage of medical instruments and pharmaceuticals.

Retail and Gift Packaging: Trays with custom shapes and branding create a premium presentation for retail products and gifts.

Final Thoughts:

The ability to customize dry press molded pulp trays makes them an attractive solution for companies looking for sustainable, tailor-made packaging. From design flexibility to the environmental benefits, investing in custom dry pressing paper pulp trays can significantly enhance a brand’s packaging strategy. Working with experienced dry press molded pulp manufacturers ensures that the trays meet quality and sustainability standards while delivering a unique and functional product. As more companies prioritize eco-friendly practices, customized dry press molded pulp trays stand out as a versatile and responsible choice for packaging needs.

FAQs:

Q1: Can Lvxin customize dry press molded pulp trays to specific product dimensions?

Yes, Lvxin specializes in creating customized dry press molded pulp trays tailored to the precise dimensions and specifications of your products.

Q2: Are Lvxin's dry press molded pulp trays eco-friendly?

Absolutely. Lvxin’s trays are made from natural, renewable fibers and are biodegradable and compostable, offering an environmentally responsible packaging solution.

Q3: What industries does Lvxin cater to for custom molded pulp trays?

Lvxin provides custom solutions for various industries, including electronics, food packaging, medical supplies, and retail.

Q4: How long does it take for Lvxin to create custom molds?

The timeline for creating custom molds varies based on the complexity of the design but typically ranges from a few days to a couple of weeks.

Q5: Can Lvxin’s dry press molded pulp trays include branding elements?

Yes, Lvxin can incorporate branding elements such as logos and unique designs to enhance your brand’s visibility.